Deburring and Surface finishing

Installation, operation training, and ongoing support!

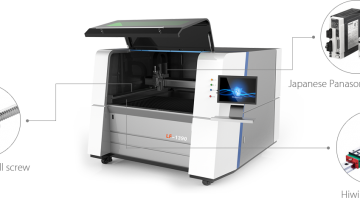

800 Series Deburring and Surface finisher

PPT specializes in high-efficiency deburring equipment for sheet metal, designed to enhance overall manufacturing performance. Our deburring machines utilize abrasive belts of varying grit sizes to handle diverse burr types and metal alloys with precision. For softer alloys, we recommend using finer grit belts, while coarser grits are ideal for tougher alloys like steel. If you’re focused on edge finishing, our edge rounding machines provide an excellent solution.

Beside deburring, PPT’s deburring machines offer multi-process capabilities, including chamfering and surface finishing, giving your products smooth and uniform surfaces. With six automated deburring solutions, our machines deliver consistent, high-precision results, eliminating dependency on operator skill level.

Working Width: 800mm

Package includes:

- 800SSR Deburring machine

- 15kW Built-in Vacuum Blower

- 5.5kW Wet Dust Collector

Curious about the deburring process best suited to your needs? Or do you have questions about specific machine models and configurations? Feel free to reach out to us for expert advice.

More Information

- Machine Introduction

This equipment is a combination model of 2 dry abrasive belts and universal roller brush. It is mainly used for deburring, chamfering, workpiece edge and hole deburring. Adjust different parameters and select suitable abrasives according to different processing requirements.

- Workpiece Surface Burr Treatment

This machine is equipped with 2 sets of wide abrasive belt mechanism, the abrasive belt rotates at high speed to remove slag particles, oxide layer, large flanging and other burrs on the surface of the workpiece.

- Deburring of workpiece edges and holes

This equipment is equipped with 2 rows (2 pcs per row, total 4pcs) of universal roller brush structure. The roller brush rotates at high speed and engages with the surface of the workpiece, so that the contour edges around the workpiece surface and in the hole are smooth and rounded, resulting in a rounded finish. For the burrs generated in the process of stamping, shearing, laser cutting, plasma cutting, etc., it can be removed in all directions at one time, so that all edges and holes of the workpiece can achieve a small radius finish. The deburring process is safe and reliable, so that the workpiece can achieve perfect results.

- Vacuum adsorption conveyor feeding

This equipment adopts high damping imported conveyor belt to transmit workpiece, the conveyor uses vacuum adsorption method to fix the workpieces. For workpieces smaller than 50mm×50mm, it needs to do special fixture and put the workpiece on the fixture. The conveyor feeding speed is adjustable.

- Four-column synchronized lifting, rolling brush position independent Lifting servo control, accuracy 0.01mm.

- Servo synchronous lifting, elevator lifting control to adjust different processing thickness, stable and

- The equipment door has power-off function, when the door is open, the power will shut down to protect the operator.

- The key parts are finished by gantry milling machine to ensure the accuracy of

- The standard universal brush abrasive has automatic compensation function eliminates the trouble of manual adjustment by operators.

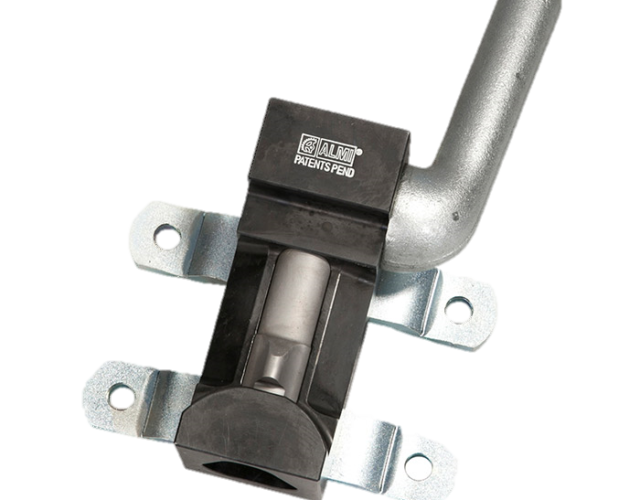

Compatible tooling & consumables

Consumables

- Abrasive Belt

- Roller Brush