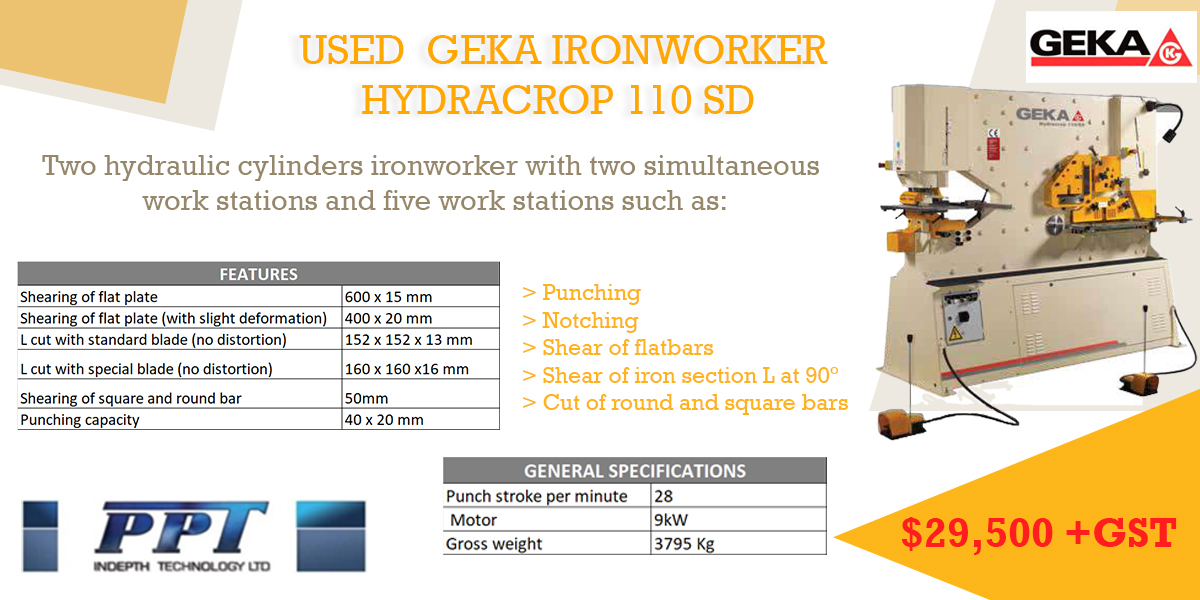

Geka 110 Hydracrop SD- USED

Hydracrop Series, Universal two-cylinder ironworkers

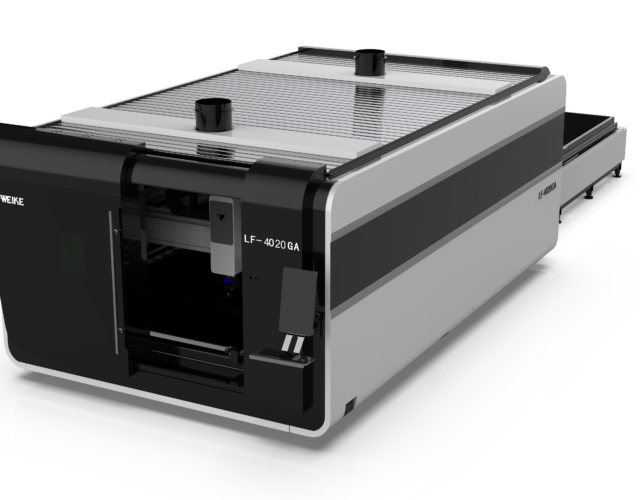

USED HYDRACROP 110 SD

PRICE: $29,500+GST

(Ex- Otahuhu)

FEEL FREE TO BOOK A DEMO TODAY!

Geka 110 Hydracrop SD- USED

PLEASE NOTE: NEW MACHINE SPECIFICATION BELOW FOR REFERENCE ONLY. PLEASE FEEL FREE TO INSPECT THE MACHINE AND BOOK A DEMO.

GEKA two-cylinder punching shears are very versatile machines with the capacity to transform all different types of sections and steel flat bars.

Two operators can use these ironworkers simultaneously, doubling production capacity. The HYDRACROP family has 5 workstations and 5 tonnage levels.

Two hydraulic cylinders ironworker with two simultaneous work stations and five work stations such as:

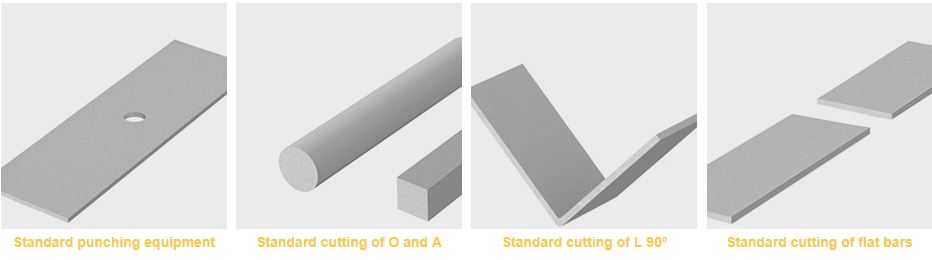

- Punching

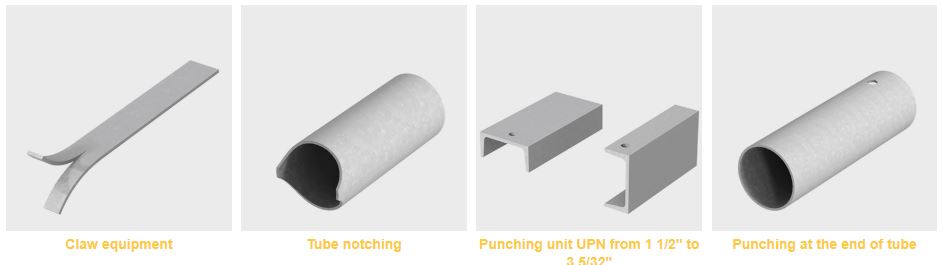

- Notching

- Shear of flatbars

- Shear of iron section L at 90º

- Cut of round and square bars

More Information

PLEASE NOTE: NEW MACHINE SPECIFICATION BELOW FOR REFERENCE ONLY. PLEASE FEEL FREE TO INSPECT THE MACHINE AND BOOK A DEMO.

| FEATURES | 55/110 | 80/150 | 110/180 | 165/300 | 220/300 | ||

| S, SD | S, SD | S, SD | S, SD | S, SD | |||

| *The first figure indicates metric tons on the punching end. | |||||||

| *The second figure, metric tons on L-shearing end. | |||||||

| SHEARS FOR PROFILES | |||||||

| Flatbar with slight deformation | mm | 300x15 | 450x15 | 600x15 | 750x20 | 750x20 | |

| mm | 200x20 | 300x20 | 400x20 | 400x30 | 400x30 | ||

| Length of blade | mm | 305 | 475 | 605 | 765 | 765 | |

| Square bar | mm | 25 | - | - | - | - | |

| Work height | mm | 880 | 850 | 960 | 870 | 870 | |

| C SHEARS FOR PROFILES | |||||||

| Shearing power | kN | 1100 | 1500 | 1800 | 3000 | 3000 | |

| L at 90º shear without deformation | mm | 120x120x10 | 130x130 x13 | 152x152x13 | 205x205x18 | 205 x205x18 | |

| L at 45º | mm | 70x70x7 | 70x70x7 | 70x70x7 | 70x70 x 7 | 70x70x7 | |

| WITH SPECIAL BLADE | |||||||

| L at 90º | mm | 130x130x13 | 152x152x13 | 160x160x16 | 205x205x25 | 205x205x25 | |

| (shear with slight deformation) | |||||||

| SHEARS FOR SOLID BARS | |||||||

| Round bar ø | mm | 40 | 45 | 50 | 60 | 60 | |

| Square bar | mm | 40 | 45 | 50 | 60 | 60 | |

| WITH SPECIAL BLADES | |||||||

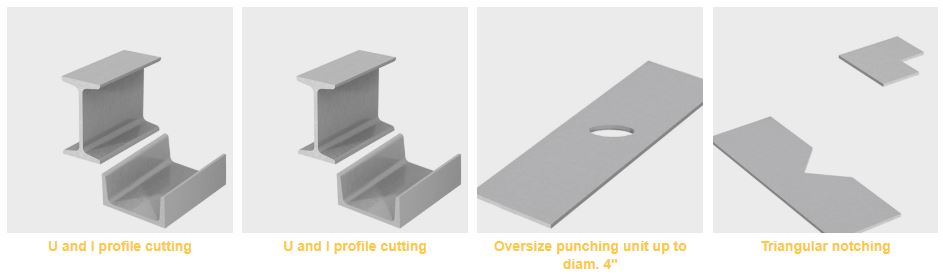

| UPN Profiles | mm | 120 | 140 | 160 | 180 | 180 | |

| IPN Profiles | mm | 120 | 140 | 160 | 180 | 180 | |

| NOTCHING | |||||||

| Plate thickness | mm | 10 | 12 | 13 | 16 | 16 | |

| L of | mm | 100 | 100 | 100 | 120 | 120 | |

| Depth | mm | 90 | 90 | 90 | 110 | 110 | |

| Width | mm | 42 | 52 | 52 | 58 | 58 | |

| PUNCHING | |||||||

| Punching Power | kN | 550 | 800 | 1100 | 1650 | 2200 | |

| Maximum capacity with quick change | mm | ø 40x10 | ø 40x14 | ø 40x20 | ø 40x30 | ||

| and die with gooseneck die holder | mm | ø 20x20 | ø 24x24 | ø 28x28 | ø 34x34 | ø 40x40 | |

| Throat depth | S | mm | 250 | 300 | 300 | 510 | 385 |

| Throat depth | SD | mm | 500 | 500 | 610 | 610 | 475 |

| Stroke | mm | 60 | 70 | 80 | 100 | 100 | |

| Work height | mm | 1085 | 1095 | 1165 | 1110 | 1110 | |

| GENERAL SPECIFICATIONS | |||||||

| Punch stroke per minute | 37 | 40 | 28 | 31 | 26 | ||

| (based on 20 mm travel) | |||||||

| Motor: | kW | 5 | 9 | 9 | 15 | 15 | |

| Approx. net weight with production pack | S | Kg | 1390 | 2070 | 2750 | 5200 | 5900 |

| SD | Kg | 1750 | 2400 | 3300 | 6300 | 7000 | |

| Gross weight | S | Kg | 1598 | 2323 | 3162 | 5980 | 6785 |

| SD | Kg | 2012 | 2760 | 3795 | 7245 | 8050 | |

| Packaging dimensions | S | m | 1,67x1,16x2,09 | 2,13x1,20x2,05 | 2,13x1,20x2,20 | 2,83x1,60x2,20 | 2,88x1,60x2,40 |

| SD | m | 2,10x1,16x2,09 | 2,31x1,2x2,05 | 2,69x1,4x2,20 | 2,95x1,60x2,20 | 3,04x1,60x2,40 | |

| Volume of maritime packing | S | m3 | 4,04 | 4,72 | 5,62 | 10 | 11,06 |

| SD | m3 | 5,09 | 6,68 | 8,28 | 10,38 | 11,67 |

Capacities based on a material resistance of 65,000 tensile

– The manufacturer reserves the right to make modifications without prior notice

“S” VERSION

- Machines driven by two cylinders.

- 5 workstations, fitted with tools for L, shearing, round and square bars, rectangular notching and punching

- Quick change punch

- Flat bar shearing table with adjustable guides

- 2 simultaneous workstations

- Greater speed backed by a powerful hydraulic unit.

- Special equipment for approaching at reduced pressure and slow speed.

- Precision punching table with X & Y measuring stops.

- Precision notching table with X & Y measuring stops

- Ready for production pack comprising:

- One meter “touch & cut” length stop with fine adjusting.

- Lamp for enhanced vision of cutting zones.

- 10 sets of round punches and dies.

“SD” VERSION

- The same features as the S version, but with a deeper throat for a larger plate and sheet metal applications.

Punching station dimensions

| A | B | C | D | E | F | G | H | I | K | L | M | N | O | P | Q | R | S | ||

| HYDRACROP 55 | S | 254 | 350 | 280 | 65 | 57 | 33 | 120,5 | 81 | 233,5 | 137 | 25 | 208 | 35 | 233 | 72 | 268 | 125 | 1066 |

| SD | 508 | 350 | 280 | 65 | 57 | 33 | 120,5 | 81 | 233,5 | 137 | 25 | 208 | 35 | 233 | 99 | 110 | 170 | 1066 | |

| HYDRACROP 80 | S | 305 | 370 | 300 | 65 | 64 | 31 | 123 | 89 | 253,5 | 144 | 25 | 234 | 45 | 304 | 120 | 250 | 120 | 1094 |

| SD | 510 | 370 | 300 | 65 | 64 | 31 | 123 | 89 | 253,5 | 144 | 25 | 234 | 45 | 304 | 130 | 70 | 225 | 1094 | |

| HYDRACROP 110 | S | 305 | 395 | 325 | 79 | 81 | 40 | 140,5 | 96 | 267 | 161 | 25 | 256 | 45 | 311 | 120 | 275 | 120 | 1151 |

| SD | 610 | 395 | 325 | 79 | 81 | 40 | 140,5 | 96 | 267 | 161 | 25 | 256 | 45 | 311 | 150 | 72 | 260 | 1151 | |

| HYDRACROP 165 | S | 510 | 450 | 380 | 85 | 79 | 47 | 158 | 104 | 322 | 200 | 25 | 369 | 45 | 450 | 160 | 80 | 160 | 1110 |

| SD | 610 | 450 | 380 | 85 | 79 | 47 | 158 | 104 | 322 | 200 | 25 | 369 | 45 | 450 | 150 | 100 | 260 | 1110 | |

| HYDRACROP 220 | S | 385 | 470 | 400 | 85 | 79 | 47 | 158 | 104 | 322 | 200 | 25 | 372 | 45 | 450 | 35 | 350 | 35 | 1090 |

| SD | 475 | 470 | 400 | 85 | 79 | 47 | 158 | 104 | 322 | 200 | 25 | 372 | 45 | 450 | 85 | 300 | 85 | 1090 | |

| Dimensions in mm. |

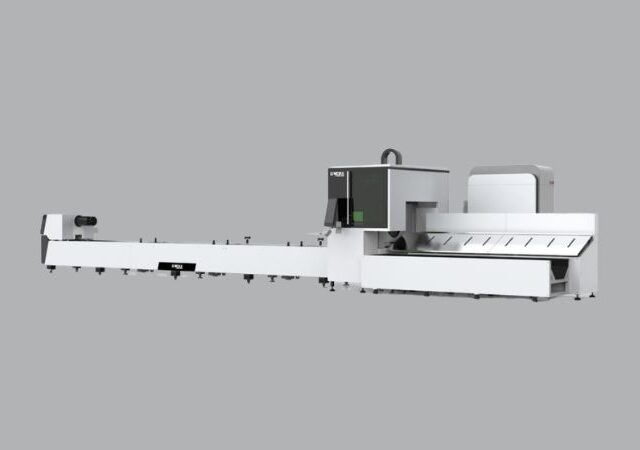

Semipaxy

The Semipaxy product line brings the newest CNC automation and positioning technology to steel punching. This unit is equipped with programmable stops along the X- and Y-Axis

PAX

PAX

The PAX product line guarantees the automated positioning of material along the X-Axis permitting sequential multiple punching of profiles.

ALRS

The ALRS product line is an automated feeder of flat bar, available as part of an option package for our HYDRACROP (except 55 tons model) shearing stations.

Recent Comments