Bendicrop Series, the only hydraulic ironworker machines that incorporate a bending station.

Ex Spain

-

BENDICROP 60S 14,550 Euro or $25,526 NZD + freight + GST [freight at cost]

Alternatively, PPT will configure a GEKA Hydracrop or Bendicrop to meet your requirement.

PPT will trade an existing GEKA provided it is in a suitable condition.

Geka Bendicrop Series

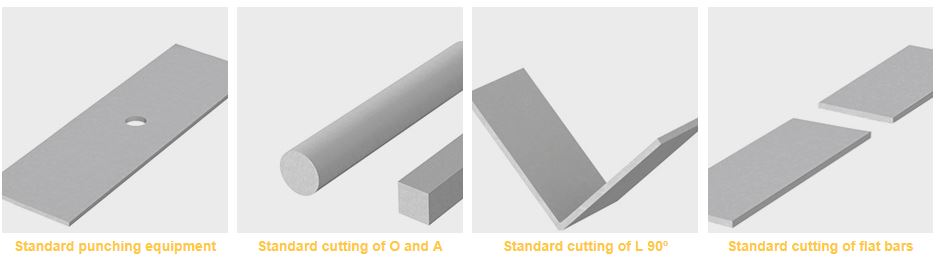

The BENDICROP models have the same workstations as the HYDRACROP, but these machines also have a permanent bending station.

The machines are therefore more complete than conventional ironworkers because they can perform bending tasks in a simple and safe way.

Bendicrop 50, hydraulic ironworker machine with 1 cylinder and a bending station.

Bendicrop 60, hydraulic ironworker machine with 2 cylinders and a bending station.

Bendicrop 85, hydraulic ironworker machine with bending station and system to avoid distortions when cutting plates.

More Information

| FEATURES | BENDICROP 50 | BENDICROP 60 S | BENDICROP 60 SD | BENDICROP 85 S | BENDICROP 85 SD | |

| SHEAR FOR FLAT BARS | ||||||

| Flat bars (low deformation) | mm | 350 x 10 | 350 x 15 | 350 x 15 | 450 x 15 | 450 x 15 |

| mm | (5º) 350 x 15 | (5º) 350x15 | (5º) 350x15 | (5º) 450x18 | (5º) 450x18 | |

| Length of blades | mm | 356 | 356 | 356 | 475 | 475 |

| Shear or one angle leg L at 45º | mm | 70 | 70 | 70 | - | - |

| Working height | mm | 810 | 859 | 859 | 868 | 868 |

| SHEARS FOR SECTION IRON | ||||||

| L at 90º | mm | 80 x 80 x 8 | 120 x 120 x 10 | 120 x 120 x 10 | 120 x 120 x 10 | 120 x 120 x 10 |

| L at 45 º | mm | - | - | - | - | - |

| Round Bar ø | mm | 35 | 45 | 45 | 45 | 45 |

| Square bar | mm | 30 | 40 | 40 | 40 | 40 |

| NOTCHING | Rectangular | Triangular | Triangular | Triangular | Triangular | |

| Plate Thickness | mm | 10 | 10 | 10 | 12 | 12 |

| Angle of | mm | 100 | 100 | 100 | 130 | 130 |

| Depth | mm | 90 | ||||

| Width | mm | 42 | ||||

| PUNCHING | ||||||

| Punching Power | kN | 500 | 600 | 600 | 800 | 800 |

| Maximum Capacity | mm | (A) ø 31 x 12 | ø 40 x 11 | ø 40 x 11 | ø 40 x 15 | ø 40 x 15 |

| (B) ø 27 x 13 | ||||||

| Throat | mm | 177 | 250 | 500 | 300 | 500 |

| Working Height | mm | 973 | 1106 | 1106 | 1094 | 1094 |

| BENDING ATTACHMENT | ||||||

| Maximum Capacity | mm | 100 x 10 | 150 x 10 | 150 x 10 | 200 x 12 | 200 x 12 |

| GENERAL SPECIFICATIONS | ||||||

| Motor | kW | 3 | 5,5 | 5,5 | 9 | 9 |

| nº strokes per minute | 34 | 32 | 32 | 40 | 40 | |

| (stroke 15mm) | (stroke 15mm) | (stroke 15mm) | (stroke 20mm) | (stroke 20mm) | ||

| Net weight | kg | 1000 | 1390 | 1750 | 2400 | 2400 |

| Gross weight | kg | 1200 | 1598 | 2012 | 2760 | 2760 |

| Packaging dimensions | m | 1,3 x 1,1 x 1,85 | 1,85 x 1,3 x 2,06 | 2,01 x 1,4 x 2,06 | 2,3 x 1,2 x 2,05 | 2,3 x 1,2 x 2,05 |

| Volume of seaworthy package | m3 | 2,65 | 6,05 | 5 | 6,68 | 6,68 |

| OPTIONAL EQUIMENTS | ||||||

| SHEARS FOR SECTION IRONS | ||||||

| U and U section iron | mm | 100 | 120 | 120 | 120 | 120 |

| PIPE NOTCHING | ||||||

| Maximum diameter | mm | 60 | 60 | 60 | 60 | 60 |

| PUNCHING LARGER DIAMETERS | ||||||

| Maximum diameter | mm | ø 100 x 4 | ø 100 x 5 | ø 100 x 5 | ø 100 x 6 | ø 100 x 6 |

Capacities based on a material resistance of 65,000 tensile

– The manufacturer reserves the right to make modifications without prior notice

Semipaxy

The Semipaxy product line brings the newest CNC automation and positioning technology to steel punching. This unit is equipped with programmable stops along the X- and Y-Axis

PAX

PAX

The PAX product line guarantees the automated positioning of material along the X-Axis permitting sequential multiple punching of profiles.