BAND SAWS, PIVOTING MOVEMENT, GRAVITY FEED, STEEL AND ALUMINUM CUT, MITER

IMET – BS 400 SHI BAND SAW- 400MM FAB CAPACITY- WITH ROLLER TABLE

Semiautomatic hydraulic bandsaw, for medium and heavy steelwork, mitre cutting up to 60° left and 45° right.

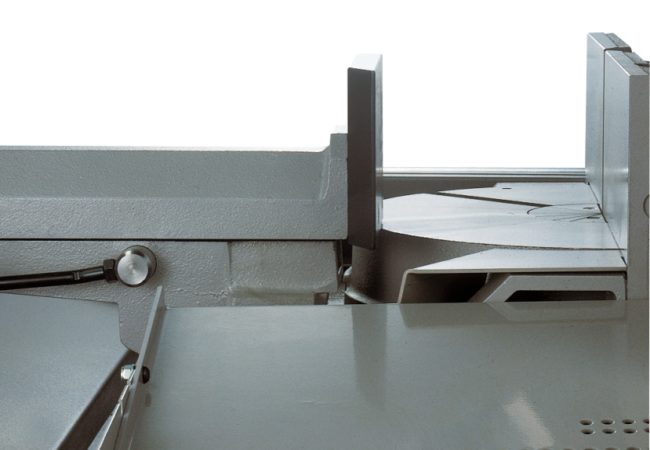

- Hydraulic vice with adjustable guides, free to move alongside the worktable, with quick motion and clamping.

- Easy stops at 0°, 45°, 60° left and 45° right. Adjustment of the blade tension from the front side of the saw-frame, checked by an end-stroke. Blade guides with hard metal pads, additional bearing for blade alignment.

- Steel saw frame with tubular section, pulleys 360 mm. diameter.

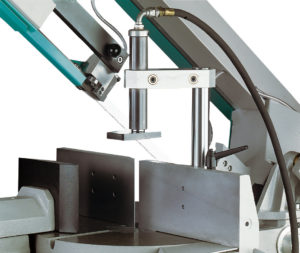

- Mechanical device (position sensor) that allows the saw frame to lower quickly toward the material and detect automatically the start-cut point.

- Wide working space 460 mm diameter with rotating table integral with the saw frame to avoid incisions of the table, rotation on thrust ring with pre-loaded thrust bearing.

- Cutting Capacity: rounds till 310 mm., square till 280 mm. and rectangular till 400×250 mm.

More Information

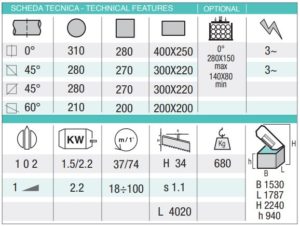

| Area angular cut | ° | - 45/90 / 30 |

| Cutting capacity at 90 °: round / square / rectangular | mm. | 310 / 280 / 400x250 |

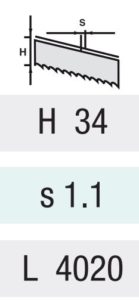

| Blade dimensions | mm. | 4020 x 34 x 1.1 |

| Blade Motor Power | KW | 1.5/2.2 or 2.2 ESC |

| Blade speed | mt / min. | 37/74 |

| Dimensions (B x W x H) | mm. | 1530x1790x2240 |

| Height of the work-table | mm. | 940 |

| Weight | Kg | 680 |

| Type of functioning | Semiautomatic hydraulic | |

| Suitable for cutting: | Steel / cast iron |

One of the features of this saw is its use of the 34mm deep x 1.1mm kerf blade. This enables it to cut heavy tubes and structural sections without deviation often experienced with the 27mm deep 0.9 kerf blade. As such this saw is a considerable step up in capability over many saws. It is also capable of cutting solid round with its 4025 mm long blade

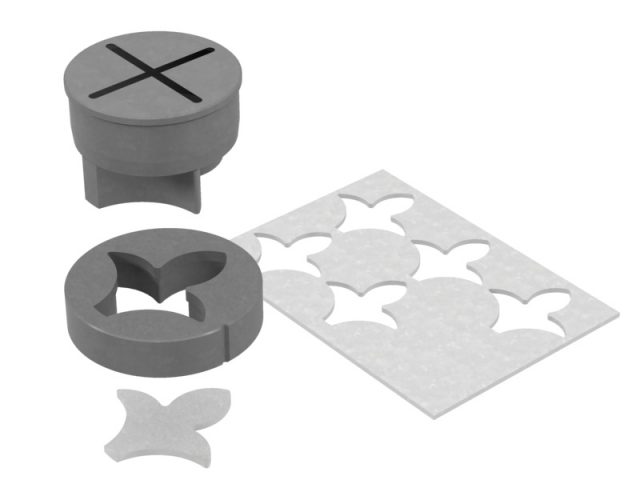

Minimal lubrication system OPTIONAL

It is possible to require, for all IMET machines, the minimal lubrication system, it avoids the dispersion of refrigerant liquid typical in the use of emulsifiable oil, the life of the blade is not in any way affected.

Column SHI

All IMET saws are designed to move the column by forklift.

Hydraulic vertical vice BS 350 SHI OPTIONAL

For saws model BS 350 (only SHI) it is possible to request a vertical hydraulic piston controlled by the vertical movement of the main vice.

Position Sensor Device BS 400

In all semiautomatic and automatic saws the detection of the start point of cutting occurs automatically through the position sensor device.

Foot Pedal Control OPTIONAL

Upon request for semi-automatic sawing machines, a foot pedal control is available.

Roller table:

- RTL 3KS600– Roller table with 75mm diameter x 600 mm heavy duty gravity rolls can be used both on loading side and unloading side, with electro welded steel structure, element of 3.0 meters.

- Support pads and a pedestal. Predisposed for the ground fixing and height adjustment

- End Stop Measuring unit knows its position from datum hence replaces tap measure and clamps for consistent cutting of lengths