IMET – KTECH 702/802/1202 F3000-6000 INDUSTRY 4.0 READY

BAND SAWS, TWIN PILLAR, AUTOMATIC, STEEL AND ALUMINUM CUT, MITER

- Vertical hydraulic vice ensures a perfect locking of the material and avoids any vibrations.

- “Clean cut” due to a standard cooling system with minimal lubrication to cut long pipe and profile without any leakage of coolant.

- Hydraulic unit of new design with new low noise pump and locking valves on all the movements, with vice pressure reducers. Most processes are carried out with switched off a hydraulic unit that allows a considerable saving of energy and maintains low the oil temperature.

IMET – KTECH 702/802/1202 F3000-6000 INDUSTRY 4.0 READY

Fully automatic twin column band saws with a hydraulic lowering of the bow and automatic miter with integrated NC control. Specially made for cutting the medium and big size of profiles, beams, pipes and also solids. Possibility to cut with a variable angle from 60° left to 60° right controlling with NC feeding and the mitering.

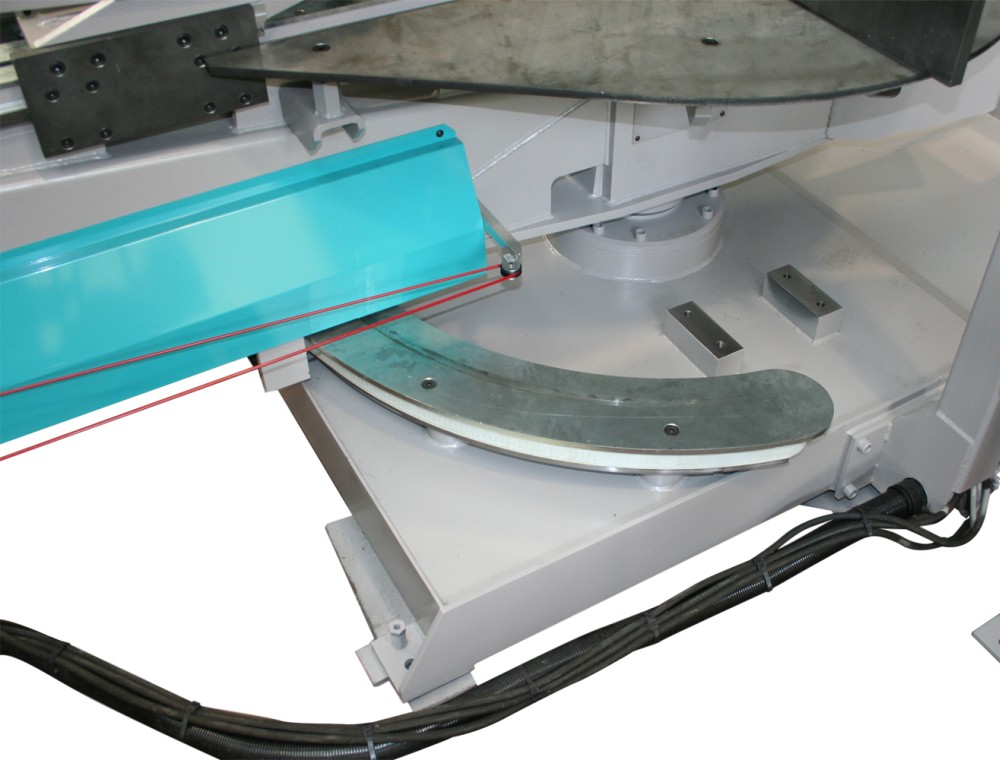

- Steel saw frame with big thickness section guarantees the absolute lack of vibration and noise, worktable supported by a central pivot with preloaded bearings.

- The rotation of the machine is made with self-braking motor and linear encoder positioned at a high distance from the centre of rotation for highest positioning precision. The hydraulic brake system of the rotation.

- The CNC driver allows setting and memorizing more than 90 cutting programs, with different cutting lengths, quantities, and angles.

- From the console, it can be regulated by the speed of feeding and force of cutting.

More Information

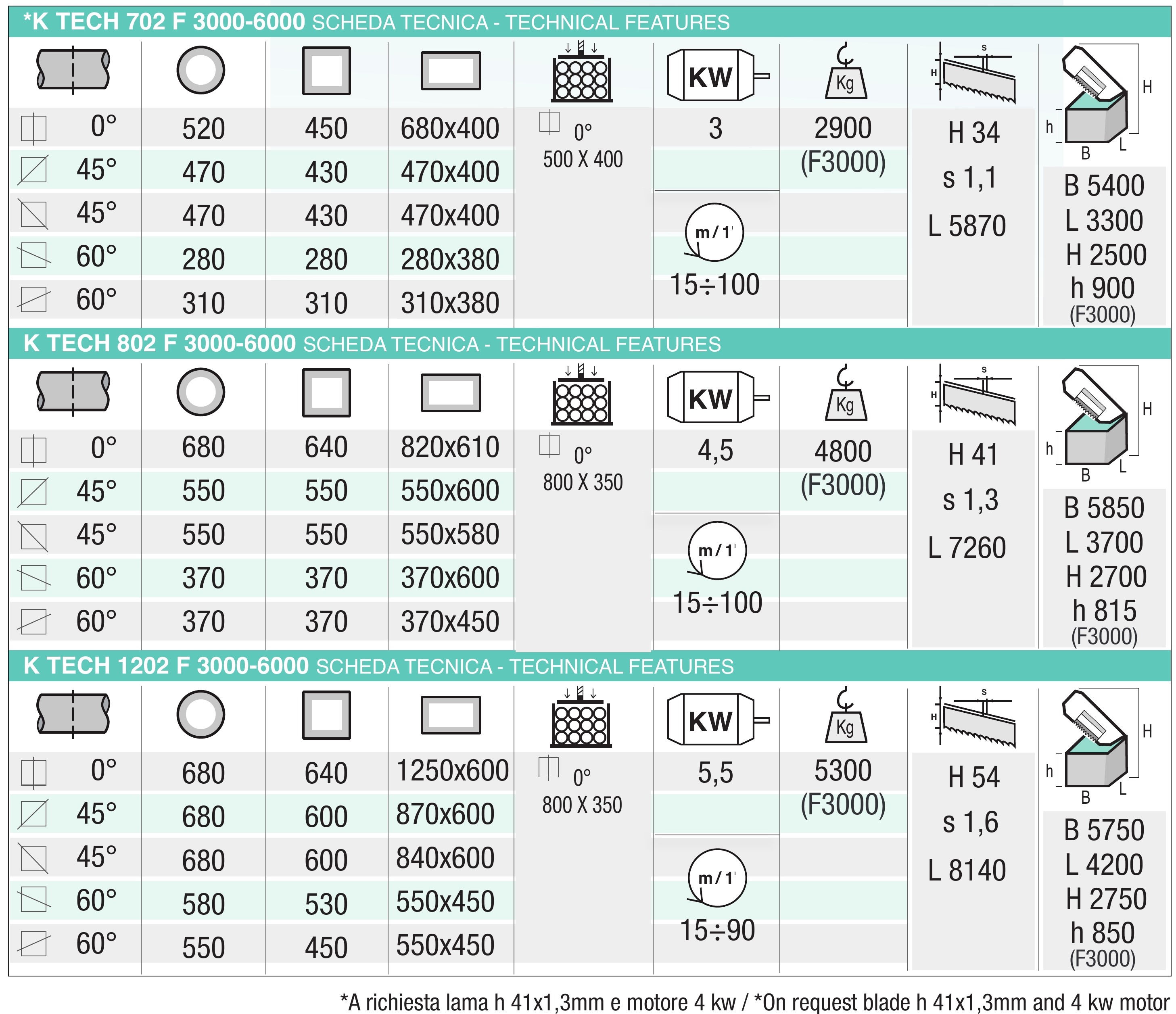

| Parameter | Unit | KTECH 702 | KTECH 802 | KTECH 1202 |

| Area angular cut | ° | -30 / 90 / 30 | ||

| Cutting capacity at 90°: round / square / rectangular | mm. | 520 / 450 / 680x400 | 680 / 640 / 820x610 | 680/640 / 1250x600 |

| Cutting capacity at 90°: rectangular with cutting bundle | mm. | 500x400 | 800x350 | 800x350 |

| Blade dimensions | mm. | 5870 x 34 x 1.1 | 7260 x 41 x 1.3 | 8140 x 54 x 1.6 |

| Inclination of the blade | ° | 6 | ||

| Blade Motor Power | KW | 3 | 4.5 | 5.5 |

| Run of the feeder carriage (repeatable) | mm. | 3000-6000 | ||

| Feeder motor power | KW | 1.5 | ||

| Scrap end | mm. | 300 | 150 | 150 |

| Blade speed | mt/min. | 15÷100 | 15÷100 | 15 ÷ 90 |

| Motor hydraulic unit | KW | 1.5 | ||

| Tank Capacity of the hydraulic unit | Lt | 80 | ||

| Capacity of the coolant tank | Lt | 3 | ||

| Dimensions ( B x L x H ) | mm. | 5400x3300x2500 ( F3000 ) | 5850x3700x2700 ( F3000 ) | 5750x4200x2750 (F3000) |

| Height of the work-table | mm. | 900 | 815 | 850 |

| Weight | Kg | 2900 ( F3000 ) | 4800 ( F3000 ) | 5300 (F3000) |

| Minimum cuttable length | mm. | 30 | ||

| Type of functioning | semiautomatic/automatic CNC | |||

| Suitable for cutting: | Steels / cast iron / high-strength steels / alloys |

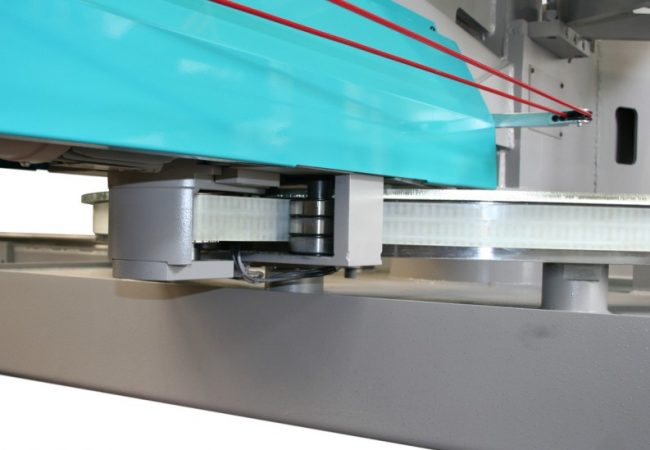

Blade Tensioning KTECHBlade tensioning through electromechanical system controlled by the CNC of the machine. |

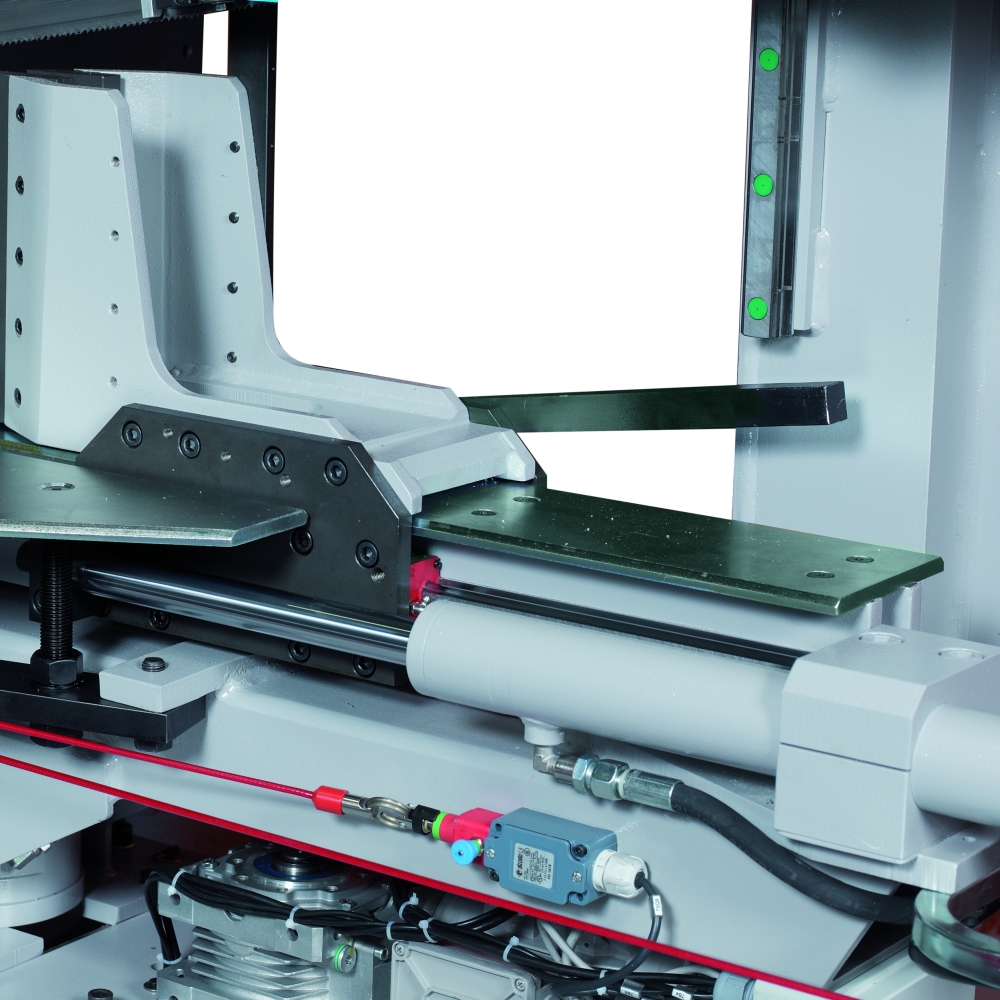

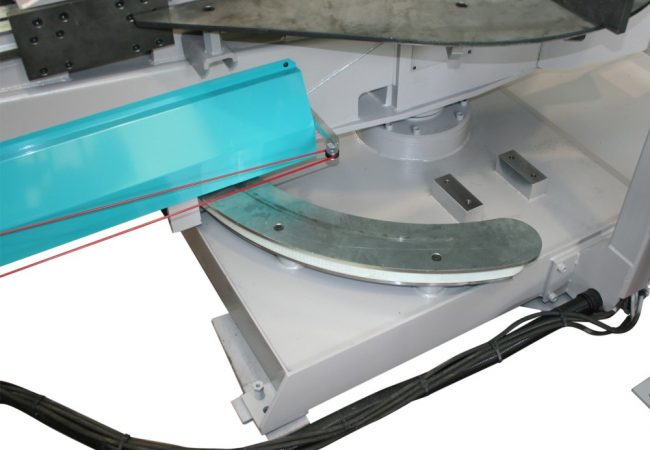

Blocking of the rotation of the Saw Frame KTECH

On the KTECH and KS NC the rotation of the saw frame is motorized and controlled by CNC, the blocking of the rotation of the saw frame takes place through a hydraulic cylinder.

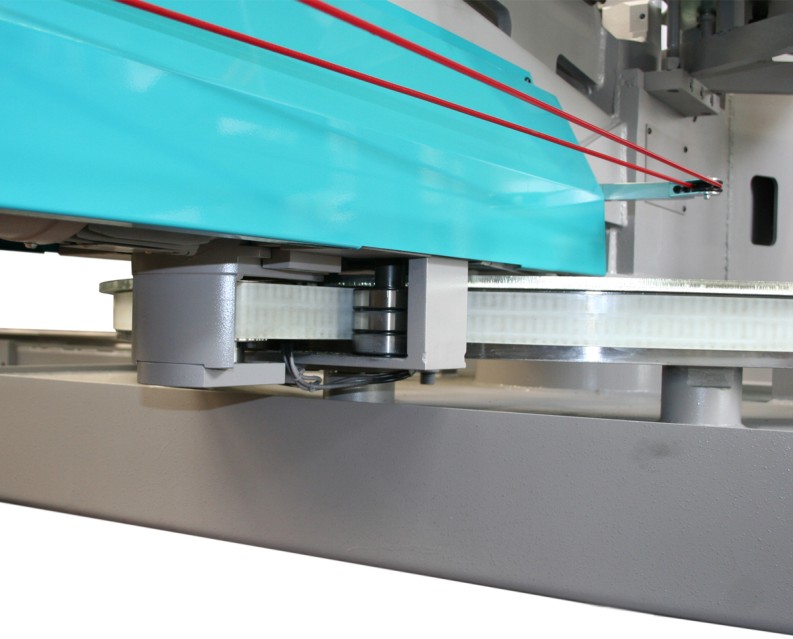

Safety Wire

As standard the Ktech Saws have a safety system through a wire which in the event of detection of an obstacle or impediment will block the operation in automatic.

Mobile Blade Guide K

On the saw machines, the mobile blade guide is automatically kept in contact with the cutting point by means of a gas piston. The minimal lubrication is standard, it avoids the dispersion of refrigerant liquid typical in the use of emulsifiable oil, the life of the blade is not in any way affected.

- Strong electro-welded steel structure which guarantees no vibrations during cutting.

- Approach device for rapid approach to the cutting area.

- Canted saw frame 6 ° to improve the penetration into the material.

- Mobile control console with adjustment of the descent speed of the saw frame and cutting thrust.

- Electronic Inverter for variable blade speed.

- Blade height 34 mm -for the 652 model, in option blade height 41 mm, 4kW motor reducer and hydraulic blade tension device

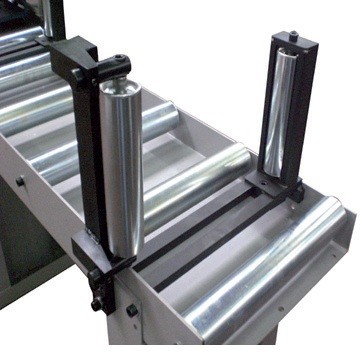

Roller tables KS

Roller tables with free rolls to be used both on loading side and unloading side , with electrowelded steel structure, element of 1,5 meters, support pads and a pedestal. Fitted for the ground fixing and with possibility of regulation of the height

Vertical Rollers RTSKS (KTech 702 & 802)

In case that your sawing machine mounts the bundle cutting device, it is advisable to request some vertical containment rollers for the material to be cut.

Recent Comments