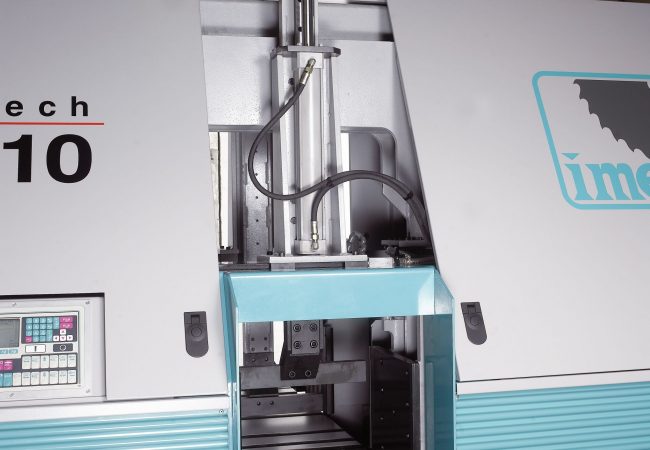

IMET – XTECH 320 INDUSTRY 4.0 READY

BAND SAWS, TWIN PILLAR, AUTOMATIC, STEEL AND ALUMINUM CUT, STRAIGHT CUT

IMET – XTECH 320 INDUSTRY 4.0 READY

Automatic CNC twin column band saws combining extremely solid mechanical structure and advanced technology to guarantee high production process and high accuracy.

- The special double section allows supporting the pulleys from both sides by a couple of big-size bearings.

- The blade guides are equipped with hard metal pads and kept hydraulically in contact with the blade.

- The blade is tensioned by a hydraulic cylinder and is controlled by the software of the saw.

- Up to 99 programs with different cutting lengths and quantity can be memorized.

- The blade speed, controlled by electronic Inverter, is infinitely variable between 12 and 100 mt/min, allowing to cut efficiently a wide variety of materials.

- For cutting till 320 mm. round and square.

More Information

| Area angular cut | ° | 90 |

| Cutting capacity at 90°: round / square / rectangular | mm. | 320 / 320 / 320x320 |

| Cutting capacity at 90°: rectangular with cutting bundle | mm. | 320x250 |

| Blade dimensions | mm. | 5095 x 34 x 1.1 |

| Inclination of the Blade | ° | 0 |

| Blade Motor Power | KW | 3 |

| Run of feeder carriage (repeatable) | mm. | 500 |

| Feeder motor power | KW | 1.5 |

| Scrap end | mm. | 80 |

| Blade speed | mt/min. | 12÷100 |

| Motor Hydraulic Unit | KW | 1.5 |

| Capacity Tank of Hydraulic Unit | Lt | 60 |

| Capacity Coolant Tank | Lt | 100 |

| Dimensions ( B x L x H ) | mm. | 2450x1850x1900 |

| Height of the Working-table | mm. | 775 |

| Weight | Kg | 2.15 |

| Minimum cuttable length | mm. | 6 |

| Type of Functioning | semiautomatic/automatic CNC | |

| Suitable for Cutting | Steel / cast iron / high-strength steels / alloys |

Chips conveyor XTECH

All automatic twin column bandsaws XTECH have the motorized chip conveyor hydraulically driven, have the rapid fitting for quick extraction in case of chip obstruction or cleaning.

Special Double Section of Saw Frame XTECH 320

Saw frame and base made of high thickness electro-welded steel, which guarantees no vibrations and long blade life. The special double section allows to support the pulleys from both sides by a couple of big-size bearings

Blade Cleaning Brush and Position Sensor Device XTECH 320

The saws XTech 320 are fitted as standard with a blade cleaning brush device, hydraulically driven, and a couple of metal brushes. Automatic detection of cutting start point to commute from fast speed to working speed.

Electrical Board XTECH 320

The electrical board of the automatic twin column bandsaws XTECH 320 is placed in the front right of the machine in a comfortable position in case of technical intervention.

Minimal lubrication system OPTIONAL

It is possible to require , for all Imet machines, the minimal lubrication system , it avoids the dispersion of refrigerant liquid typical in the use of emulsifiable oil, the life of the blade is not in any way affected.

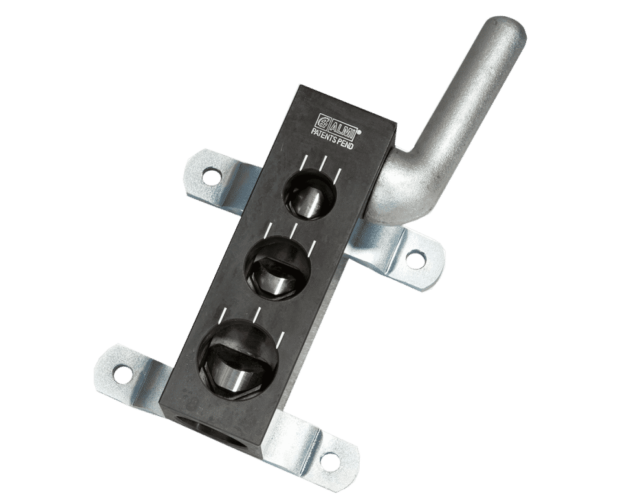

Bundle cutting OPTIONAL

On the sawing line XTech it is possible to request the hydraulic device for the bundle cutting, consisting of two vertical cylinders which allows to make cuts up to a minimum diameter of 20 mm. Download the brochure to view the saw cutting capabilities.

Feeder carriage XTECH 320

In the automatic XTech 320 bandsaws, the feeder carriage is mounted on prismatic guides and is laterally translating to load without problems also not perfectly straight material.

Roller Tables RTS XTECH

Roller tables with free rolls, a standard element with lengths of 2 meters, beam structure in the electrowelded steel of big dimensions with 5 heavy rolls on a central pivot, and bearings on both sides and two vertical rollers. Upon request double couple of vertical rollers with an adjustable width (in case of bundle cutting) and coolant collector. Prepared for the ground fixing and with a possibility of height adjustment.

Recent Comments