TOPSINN Dust Extraction for Plasma and Laser Cutting Machines

TOPSINN Dust Extraction for Plasma and Laser Cutting Machines

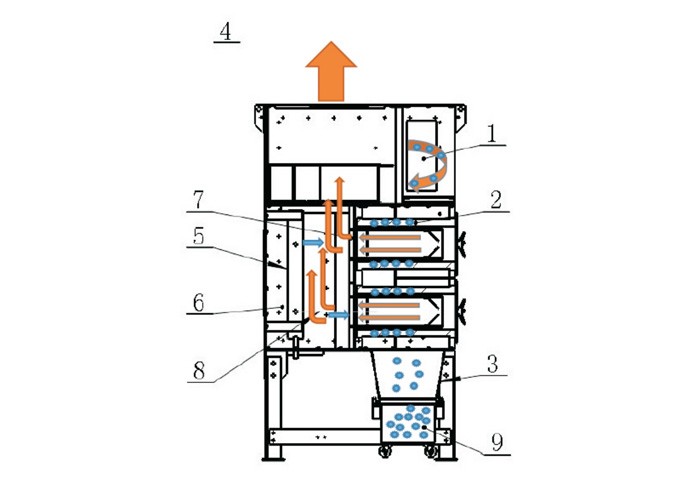

TOPSINN DUST COLLECTOR EXHAUST SYSTEM TODC

TODC 4L:FOR 3015/4020 SHEET METAL SIZE CUTTING / 6METER TUBE CUTTING

TODC 6L:FOR 6020/6025 SHEET METAL SIZE CUTTING

TODC 8L:FOR 8025 AND ABOVE SHEET METAL SIZE CUTTING

More Information

| 1. | Air inlet |

| 2. | Filter element |

| 3. | Ash bucket |

| 4. | Clean air outlet |

| 5. | Air storage tank |

| 6. | Electromagnetic pulse valve |

| 7. | Flower board |

| 8. | Pulse back blowing compressed air |

| 9. | Dust fall |

| MODEL | TODC-4L | TODC-6L | TODC-8L |

| Filter cartridge material | HV/Ahlstrom/TORAY,F9 | HV/Ahlstrom/TORAY,F9 | HV/Ahlstrom/TORAY,F9 |

| Number of Filter cartridge | 4 | 6 | 8 |

| Air volume | 3200m3/h | 4000m3/h | 7000m3/h |

| Air pressure | 3000 | 3600 | 5000 |

| Filtration efficiency | 99.99% | 99.99% | 99.99% |

| Filtering area | 82M2 | 120M2 | 166M2 |

| Centrifugal fan | 5.5KW SIEMENS | 7.5KW SIEMENS | 11KW SIEMENS |

| Collector capacity | 45L | 50L | 90L |

| Power requirments | THREE-PHASE FIVE-WIRE, 380V | THREE-PHASE FIVE-WIRE, 380V | THREE-PHASE FIVE-WIRE, 380V |

| Pressure requirement | 0.6MP, compressed air without oil and water | 0.6MP, compressed air without oil and water | 0.6MP, compressed air without oil and water |

| Unit weight | 700KG | 900KG | 1200KG |

| OutlineDimension(mm) | A:2198,B:1348, C:1060,D:303 | A:2807,B:1423, C:1180,D:383 | A:2807,B:1423, C:1180,D:383 |

FAQ

Q: Why is it important to use a Laser Cutting Dust Collector?

A: Laser cutting generates a lot of fine dust and debris that can be harmful to your health and also cause damage to your laser cutting machine. A Laser Cutting Dust Collector helps to protect your health by removing the hazardous fumes and particles from the air and also helps to keep your laser cutting machine running efficiently.

Q: How does a Laser Cutting Dust Collector work?

A: A Laser Cutting Dust Collector uses suction to extract the fumes and debris that are generated during the laser cutting process. The suction is generated by a fan or blower that pulls the dust and debris into a filter or collection bag. The filtered air is then exhausted outside or recirculated back into the room.

Q: What factors should I consider when choosing a Laser Cutting Dust Collector?

A: When choosing a Laser Cutting Dust Collector, you should consider the size of your laser cutting machine, the type of materials you will be cutting, the amount of dust and debris generated, and the location of your workshop. You should also consider the cost and maintenance requirements of the dust collector.

Recent Comments