IMET – BS 350 PLUS GH AUTOCUT BAND SAW

BAND SAWS, PIVOTING MOVEMENT, GRAVITY FEED, STEEL AND ALUMINUM CUT, MITER

IMET – BS 350 PLUS GH AUTOCUT BAND SAW

Very versatile machine with gravity descent (GH) for maintenance cutting, small and medium series production of both mechanical and carpentry for corner cuts up to 45 ° right and 60 ° left.

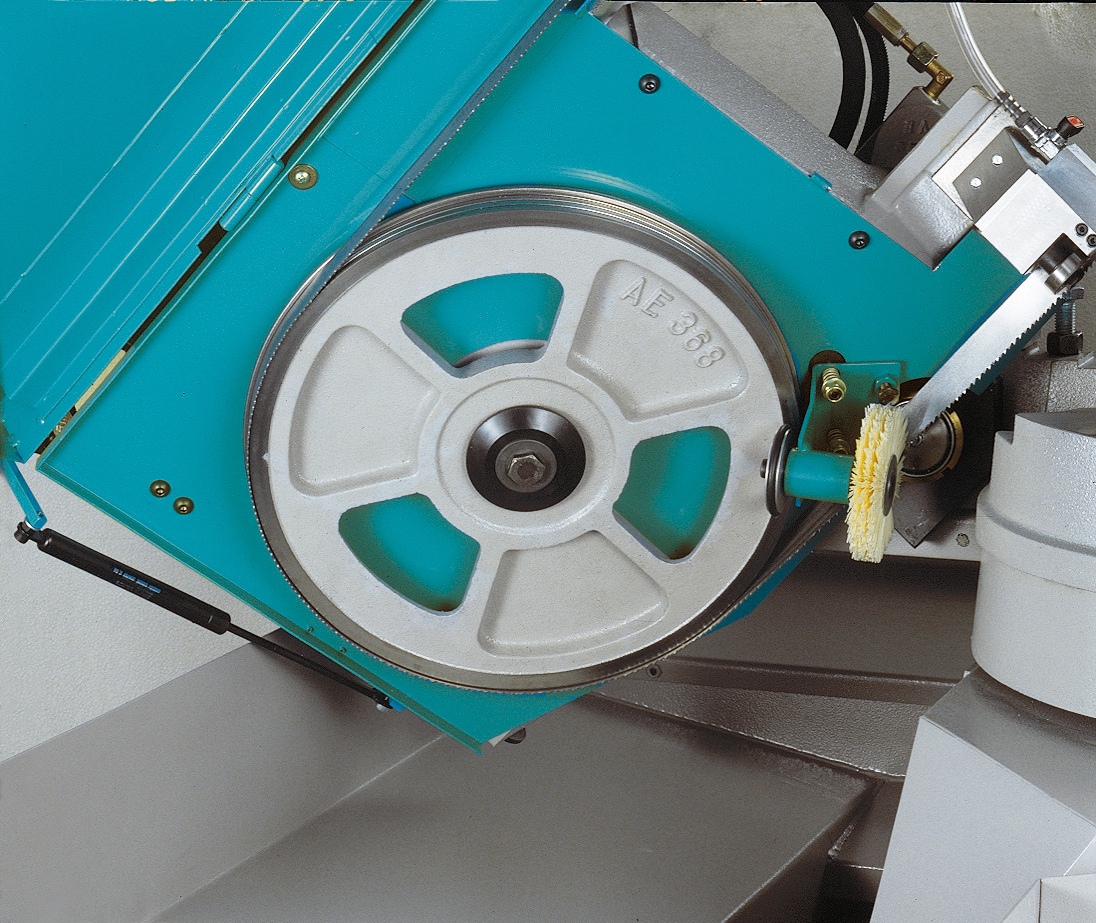

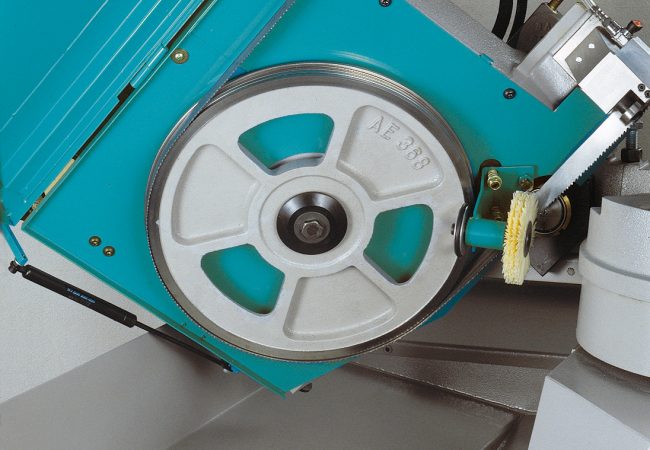

- Rigid steel arch with tubular section and 360 mm pulleys.

- Hinged blade cover casing with support piston for quick and easy blade change.

- Brush clean motorized blade.

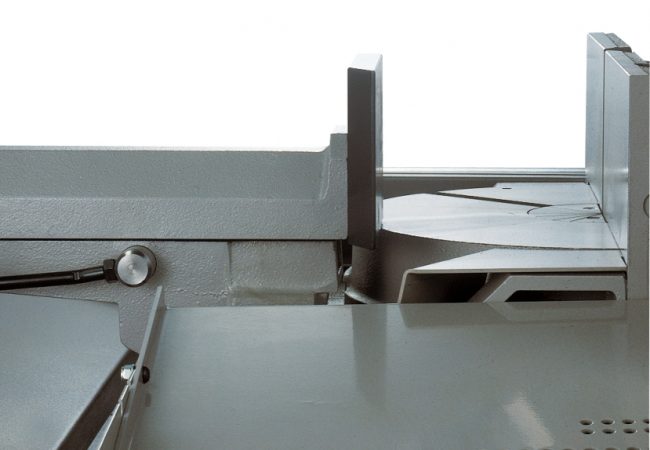

- Vice on adjustable guides, sliding transversely to the work surface, with a rapid approach.

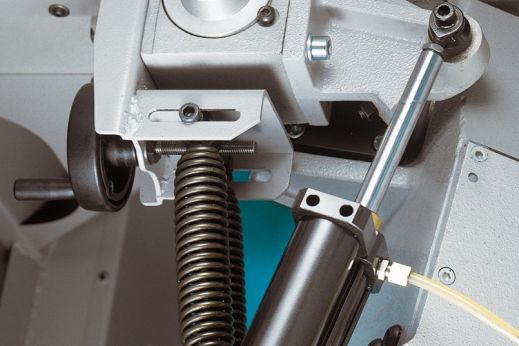

- Blade guide pads with carbide inserts and additional bearings for better blade alignment.

- Ample work space with rotary table integral with the arch to avoid incisions mounted on a roller bearing diam. 460 mm and preloaded thrust bearing.

- Very high belt tension of 1900 kg / cm² with frontal adjustment and control microswitch.

- Round cut up to 305 mm, 260 mm square, and rectangular 350×200 mm.

More Information

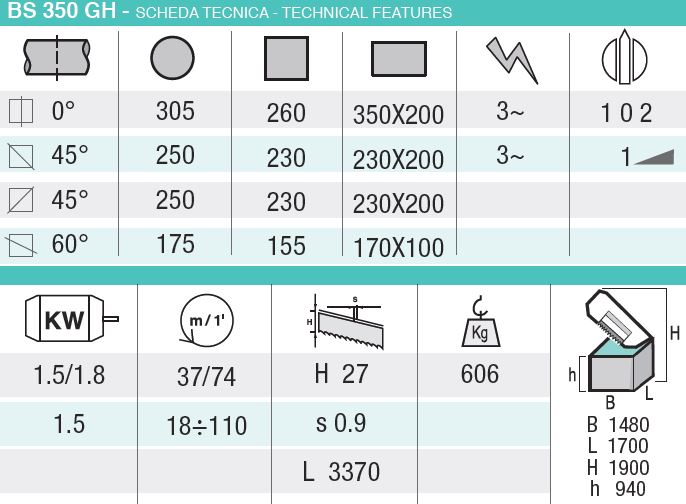

| Area angular cut | ° | - 45/90 / 30 |

| Cutting capacity at 90 °: round / square / rectangular | mm. | 305/260 / 350x200 |

| Blade dimensions | mm. | 3370 x 27 x 0.9 |

| Blade Motor Power | KW | 1.5 / 2.2 or 2.2 ESC |

| Blade speed | mt / min. | 37/74 |

| Dimensions (B x W x H) | mm. | 1480x1700x1900 |

| Height of the work-table | mm. | 940 |

| Weight | Kg | 610 |

| Type of functioning | Manual / Gravity | |

| Suitable for cutting: | Steel / cast iron |

Wide working space 460 mm diameter with rotating table integral with the saw frame to avoid incisions of the table, rotation on thrust ring with pre-loaded thrust bearing.

Blade tension 1900 kg/cm² adjustable from the front side of the saw frame, checked by an end-stroke.

- Blade guides with hard metal pads, additional bearing for blade alignment.

- Steel saw frame with tubular section, pulleys 360 mm diameter.

- Selector for a quick motion of the saw frame toward the material, then the saw frame lowers automatically with adjustable down-feed rate and the blade stops at the end of the cut.

- Manual lift of the saw frame after the cut.

- Connection for loading table equipped with a roller, 400 mm wide. Slide on the unloading side which can be transformed in connection for unloading table. Adjustable bar stop, blade-cleaning brush, bi-metal blade.

- Orientable control box with the main switch with minimum tension coil, emergency button, thermic and magnetic motor protection, motor absorption device. Floor stand with inside room and door, removable chip collector, coolant tank and electro-pump.

Recent Comments