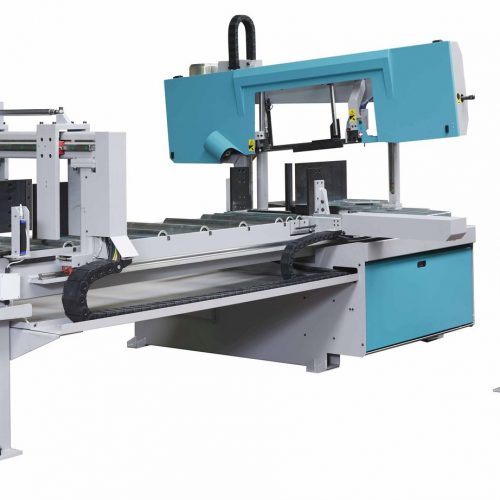

IMET – KS 502/ KS 652 -DUAL COLUMN BAND SAW

TWIN PILLAR, SEMI-AUTOMATIC, MITER

IMET – KS 502/ KS 652 -DUAL COLUMN BAND SAW

Semiautomatic hydraulic band saw specially designed for cutting medium and big size of pipes and profiles and beams. Miter cutting up to 60° left and right.

- Strong electro-welded steel structure which guarantees no vibrations during cutting. Approach device for rapid approach to the cutting area. Canted saw frame 6° to improve the penetration into the material. Mobile control console with adjustment of the descent speed of the saw frame and cutting thrust. Electronic inverter for variable blade speed. Blade height 34 mm and in option blade height 41 mm (KS652 series).

More Information

- New twin-column semiautomatic hydraulic band saw specially designed for cutting the medium and big size of pipe and profile.

- The only saw in its range that allows to cut right and left till 60°, by positioning once the blocking vice. Miter cutting up to 60° left and right, with easy stops at 0°, 45° left and 45° right.

Steel saw frame with tubular section canted 6° allows saw blade to freely and easily cut through the bottom of a structural section without vibration, binding, or slowdown of sawing rates; worktable supported by a central pivot with preloaded bearings for very easy rotation, pulleys diameter 360 mm. - Full stroke hydraulic vice free to move alongside the worktable, supported by circulating-ball screws, with quick motion and clamping, vice opening 510 mm.

- Complete with a pressure reducer. Position sensor that allows the saw frame to lower quickly toward the material and detect automatically the start-cut point and micro switch set on the blade guide to detect automatically the end cut

- point.

- Adjustment of the down-feed power and speed.

- Three-way selector to choose different working modalities: the return of the saw frame with the blade still or with the blade running, or end of the cutting cycle without the return of the saw frame.

- Support roller on both sides, 630 mm wide, which can be connected to roller tables.

- Control lights on the control panel to check: blade tension, blade cover, motor thermic overload, power supply.

- Controls console, movable for positioning.

- Floor stand with removable chip collector and coolant tank with electro-pump, a hydraulic unit with oil; motorized blade-cleaning brush trough motor pulley movement, bimetal blade.

- Strong electro-welded steel structure which guarantees no vibrations during cutting.

- Approach device for rapid approach to the cutting area.

- Canted saw frame 6 ° to improve the penetration into the material.

- Mobile control console with adjustment of the descent speed of the saw frame and cutting thrust.

- Electronic Inverter for variable blade speed.

- Blade height 34 mm (for the 652 model, in option blade height 41 mm, kW4 motor reducer and hydraulic blade tension device)

Roller tables KS

Roller tables with free rolls to be used both on loading side and unloading side , with electro-welded steel structure, element of 1,5 meters, support pads and a pedestal. Fitted for the ground fixing and with possibility of height adjustment.

Roller tables RTL

Roller tables with freerolls to be used on the unloading side, with manual movement, length stop and reading of the measure through LCD display, the length stop slides on balls recirculation guide, available in forms from 3 meters.

Roller tables RTP

Loading-unloading tables with a motorized movement of the length stop with the possibility to plan 10 different lengths through PLC. Movement through the toothed strap and geared motor on ball recirculation guides. Length stop through a pneumatic cylinder. Reading of the position through encoder and rack. Available in forms of 3 meters. Automatic withdrawal of 50 mm to facilitate the unloading of the cut piece, return in position through a button on the control.

Recent Comments