Fiber Laser Welder, cutter

Ready for Demo!

2000W Air-cooled Handheld Laser Welder- Cleaner

G W Laser Tech – 2000w Air cooled fiber laser Welder & Cutter

(Cleaner- Optional Extra)

This Air cooled Fiber Laser Welder and cutter offer following advantage

- MAX output power 2000W

- 976nm pump technology ,high efficiency WPE ≥42%

- Simple pendulum welding head, adjustable welding width

- Weight <60kg, compact design ,small size

- Air cooling technology, ultra energy-saving

- Triple safety protection, build-in air pressure monitoring.

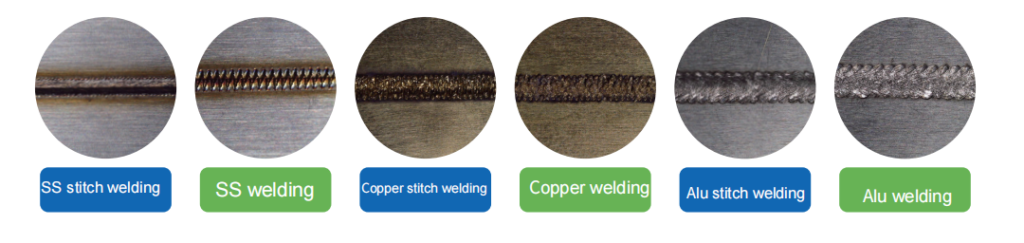

- Different material : Mild steel , Stainless steel , Aluminum , Copper, Brass , etc .

More Information

Features:

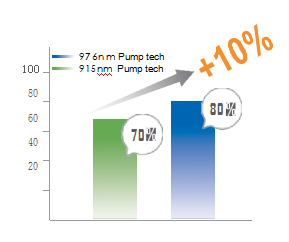

Higher Efficiency

- Independent intellectual property rights 976nm high-efficiency energy-saving technology,high-brightness single-module laser technology

- New air-cooled technology platform architecture, active refrigerant type heat dissipation

Portable

- The weight and volume are better than water cooled hand-held laser welding machine, and the volume is about 1/4, the weight is about 1/3 of it

- Extremely lightweight body, so that the application scene has nearly doubled, take it with you, plug and play (220V)

- The integrated body design conforms to ergonomics and improves the mobile reliability of the whole machine

Easy to Operate

- Compared with operating traditional welding machines, novice welders do not need a lot of time training and experience accumulation, and only need a few hours of learning to get started easily

- The machine presets 55 sets of commonly used welding parameters, which can be quickly switched to the best welding parameters according to different materials and thickness.

- Set parameters through the panel, the operation is very intuitive and concise, and can be customized and saved at the same time

Better performance

- In different materials and thickness, better welding effect, without distortion, undercut or burn-through.

- The process is smooth and beautiful, deep penetration, small deformation, no need for subsequent processing

Improve Efficiency

- Compared with the traditional welding method, it has unparalleled speed advantage, and the efficiency can reach nearly 10 times in some scenarios.

- The welding seam is beautiful and has no deformation, which improves the one-time pass rate of the workpiece, only a small amount of solder splashes, reduces the subsequent grinding and polishing process, improves the pass rate, improves efficiency, reduces waste, and reduces the cost of workpieces

| Application | Power | Maxinum Thickness of Aluminum (mm) | Maxinum Thickness of Stainless Steel (mm) | Maxinum Thickness of Mild Steel (mm) |

| Welding (Handheld) | 2000W | 6mm | 7mm | 7mm |

| Cutting (Handheld) | 2000W | 2mm | 2mm | 2mm |

| Cleaning (Weld Seam) | 2000W | No Limit | No Limit | No Limit |

Applications

The laser welding machine is widely used in making kitchen cabinets, staircase elevator, shelf, oven, stainless steel door and window guardrail, distribution box, stainless steel furniture, and other industries.