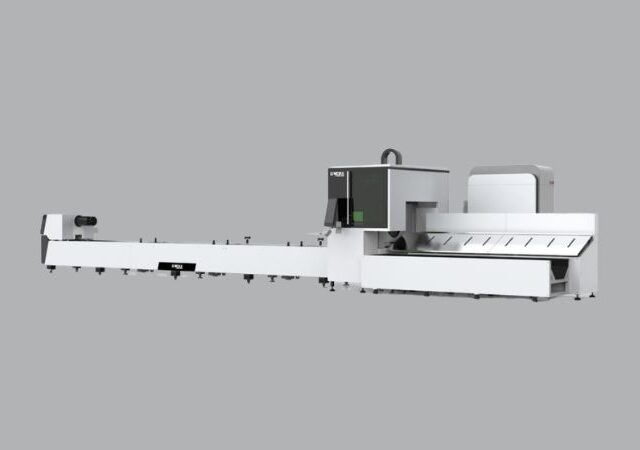

BAND SAWS, TWIN PILLAR, AUTOMATIC, STEEL AND ALUMINUM CUT, STRAIGHT CUT

IMET – XSMART3

Automatic hydraulic double column saw with robust mechanical structure associated with advanced technology, the new xsmart responds for automatic high production series

- CNC control for programming multiple lengths and quantities on the same bar

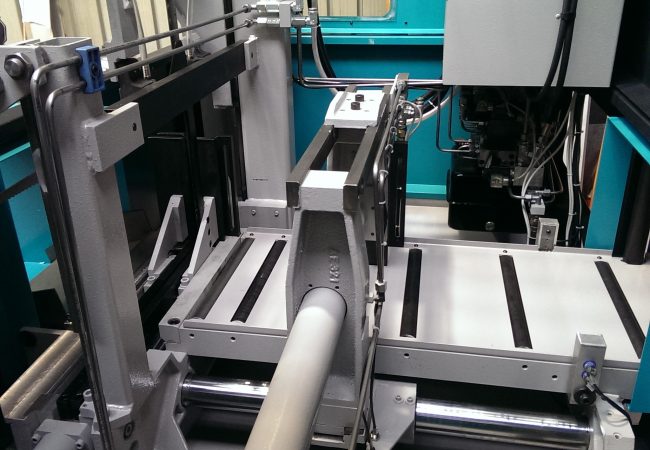

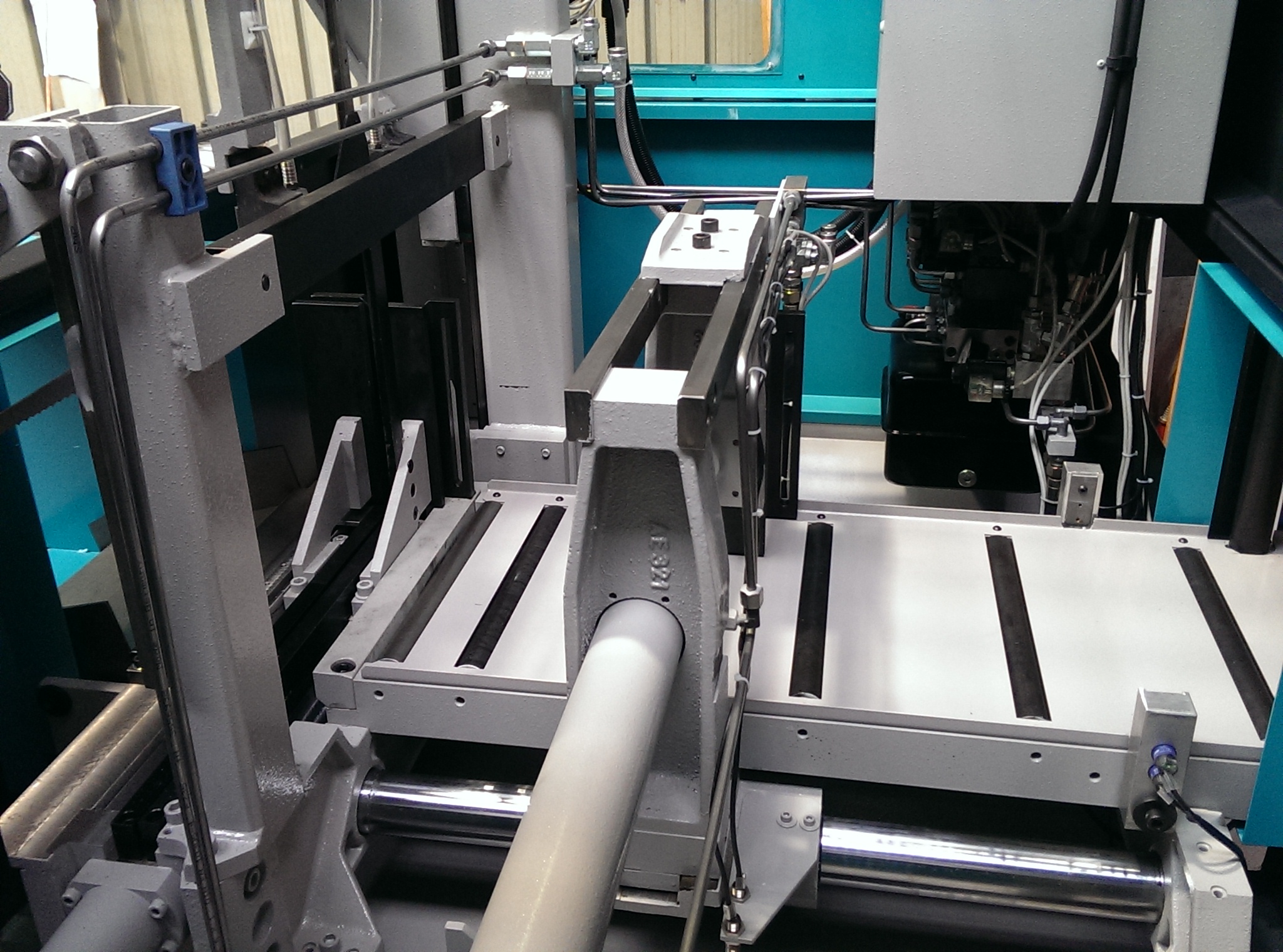

- Feeder carriage with bridge structure and roller conveyor for material support

- Material feed by the electric motor and recirculating ballscrews

- Double vice for clamping the workpiece before and after the blade

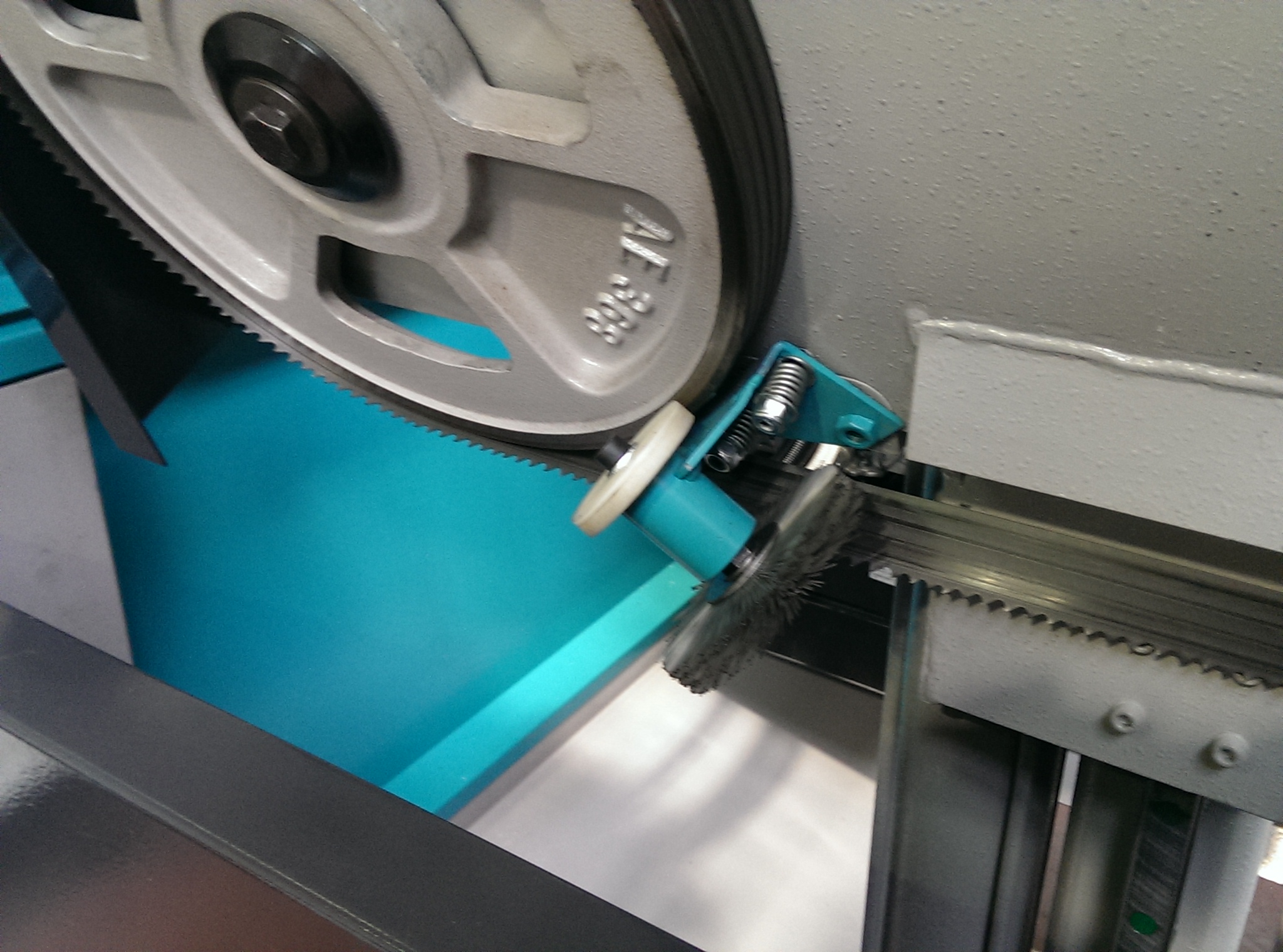

- Pulleys Inclination of 30 degrees allows to extend the life of the blade

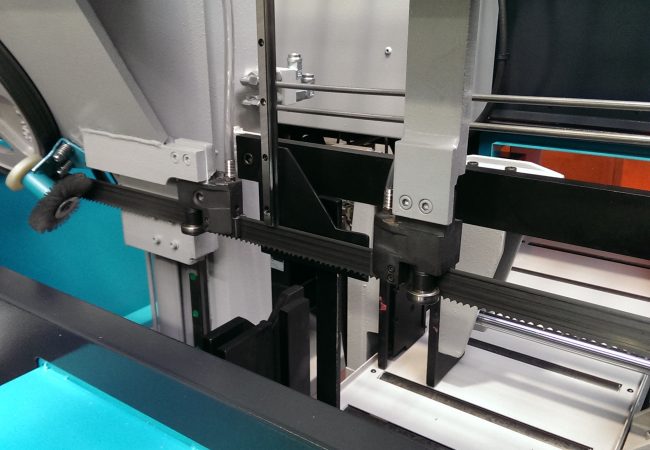

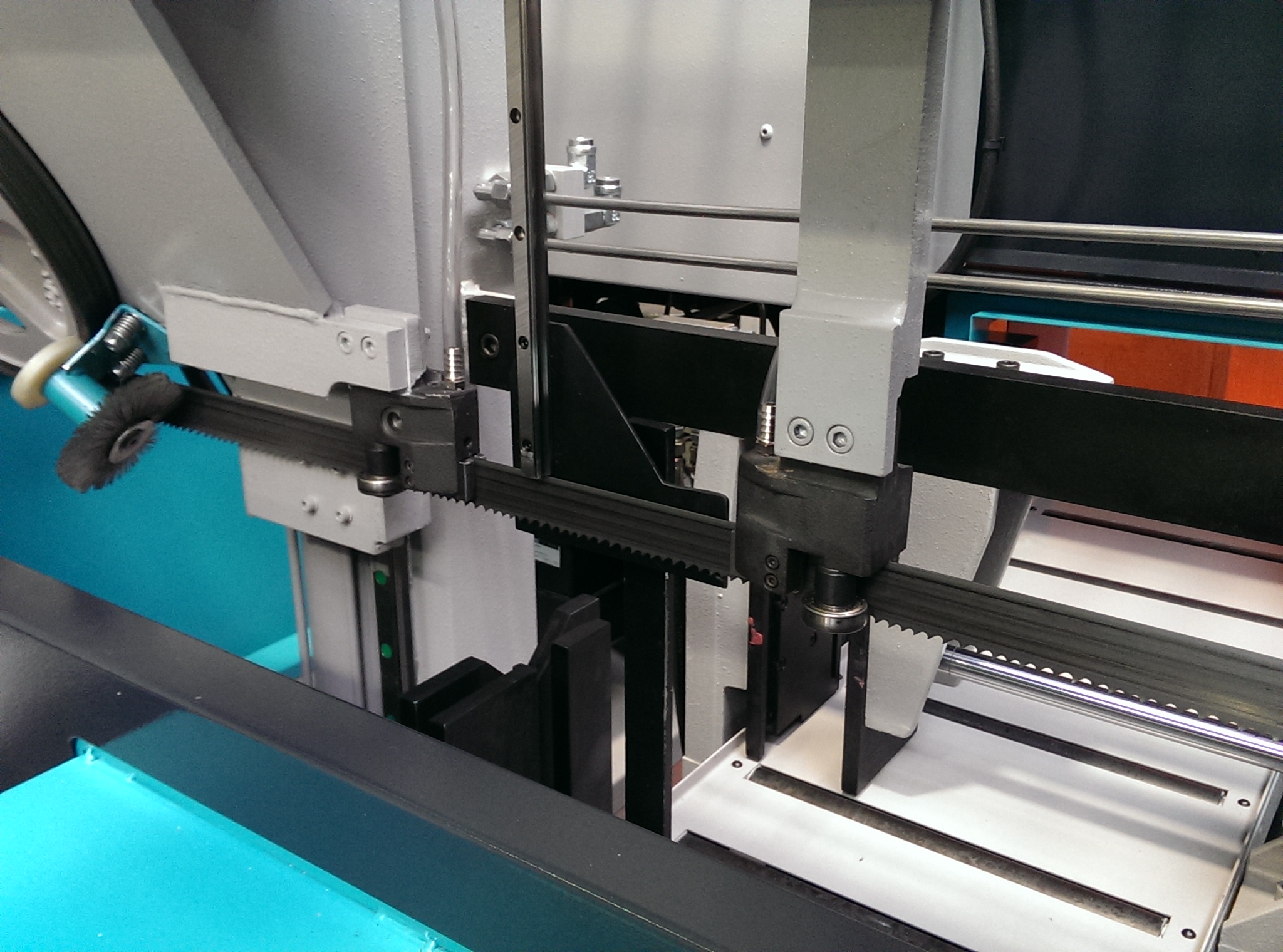

- Double column saw frame with sliding on linear guides recirculating ballscrews

- Sliding of the mobile blade guide on linear guides and recirculating ballscrews, with automatic approach of the workpiece

- Sensor for automatic detection of the start cut point

- Standard vice pressure adjustment

- Standard cutting pressure adjustment

- Mobile console

- Led light for lighting the working area

- Completely covered with easy access for maintenance

- Electric conveyor chips as optional

- Final scrap-end 50 mm

- Washing Gun

- Double Clamp Bridge feeder structure with roller tables support

- Cleaning motorized brush

More Information

| Area angular cut | ° | 90 |

| Cutting capacity at 90°: round / square / rectangular | mm. | 310 / 310 / 340x310 |

| Cutting capacity at 90°: rectangular with cutting bandle | mm. | 340x250 |

| Blade dimensions | mm. | 3730 x 34 x 1.1 |

| Inclination of the Blade | ° | 0 |

| Blade Motor Power | KW | 3 |

| Run of feeder carriage (repeatable) | mm. | 500 |

| Feeder motor power | KW | 0.75 |

| Scrap end | mm. | 50 |

| Blade speed | mt/min. | 15÷100 |

| Motor Hydraulic Unit | KW | 0.75 |

| Capacity Tank of Hydraulic Unit | Lt | 20 |

| Capacity Coolant Tank | Lt | 50 |

| Dimensions ( B x L x H ) | mm. | 1950x1755x1965 |

| Height of the Working-table | mm. | 922 |

| Weight | Kg | 1650 |

| Minimum cuttable length | mm. | 10 |

| Type of Functioning | semiautomatic/automatic CNC | |

| Suitable for Cutting | Steel / cast iron / high-strength steels / alloys |

| SMART portal feeder carriage |

| Carbide guide pads |

| XSMART motorized blade cleaning brush |

Roller tables RTS

Roller tables with freerolls, to use for loading side and unloading side, made of an electro-welded steel structure in forms of 2 meters each, with 7 galvanized steel rolls (of PVC for Velox models), the first element is with two adjustable height pedestals , the following ones with a single pedestal. They include plates of protection among the rolls to avoid crushing. The structure is completely closed to avoid dispersions of coolant.

Vertical rollers RTS

To be combined with roller RTS, if the bundle cutting device is required, it is advisable to apply these vertical rollers on the roller table to hold over the entire length of the beams material (up to 6 pairs every 2 meters in length).