BAND SAWS, TWIN PILLAR, SEMI-AUTOMATIC, STEEL AND ALUMINUM CUT, MITER

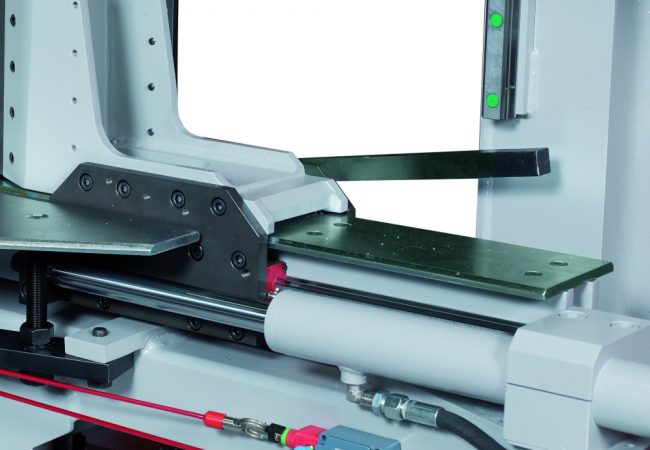

- All movements of the sawing machine are on last generation recirculating ball screws guides. (arch movement, vices and band guide) with static and dynamic high load capacity and ensure low friction sliding. Registrable band guides with hard metal pads and guided bearings.

- The mobile band guide is automatically kept as near as possible to the cutting area. Electronic Inverter for variable blade speed. Driving console movable for a useful and secure positioning, equipped with power and speed regulation bow lowering. Mechanical tensioning of the blade checked by micro switch (through hydraulic cylinder on version KS 802- KS 1202), immediate stop in case of breaking down or wrong tension.

- Floor stand with removable chip collector, hydraulic unit with oil. Motorized blade-cleaning brush, bi-metal blade.

IMET – KS 702/802/1202 NC

- Semiautomatic twin column band saws with hydraulic lowering of the bow and motorized mitring by CNC control.

- Conceived and projected especially for cutting big profiles, beams, pipe and also solids. Possibility to make cuts with variable angle from 60° left to 60° right in automatic cycle.

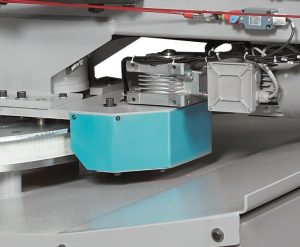

- The rotation of the machine is made with geared motor and linear encoder positioned at a high distance from the centre of rotation for highest precision in the position with hydraulic locking of the rotation.

- Automatic detection start/end cut points.

- Against the common use the canted 5° (10° for KS702) saw frame allows saw blade to freely and easily cut through the bottom of structural section without vibration, binding, or slowing down of sawing rates.

- The steel welded arch with new design and big thickness section guarantees the absolute lack of vibration and noise.

- The special section with inclined pulleys ensures a minor twist of the blade extending the life of the tool.

More Information

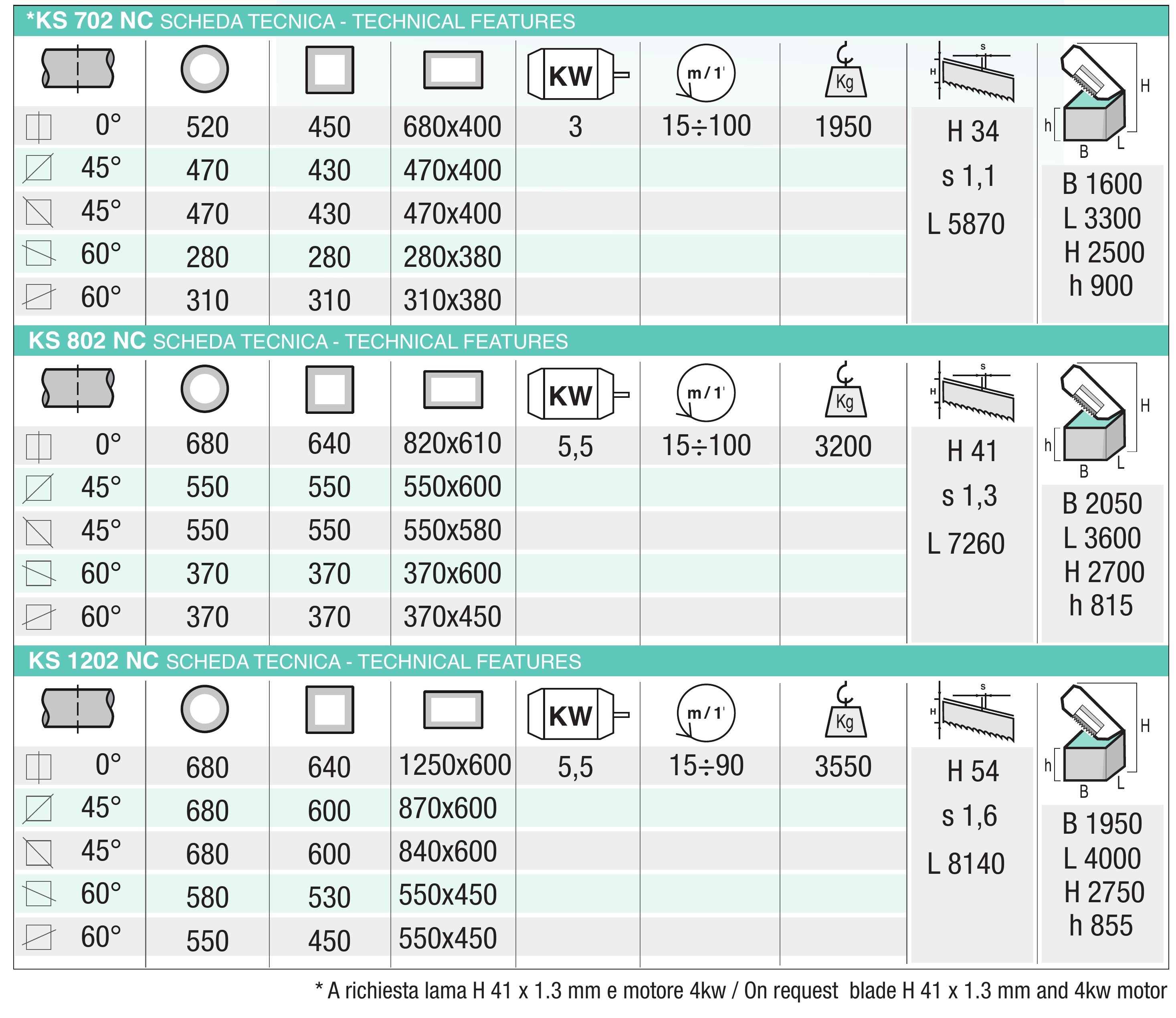

| Parameter | Unit | KS 702 | KS 802 | KS 1202 |

| Area angular cut | ° | -30 / 90 / 30 | ||

| Cutting capacity at 90°: round / square / rectangular | mm. | 520 / 450 / 680x400 | 680 / 640 / 820x610 | 680 / 640 / 1250x600 |

| Blade dimensions | mm. | 5870 x 34 x 1.1 | 7260 x 41 x 1.3 | 8140 x 54 x 1.6 |

| Inclination of the blade | ° | 6 | 5 | 5 |

| Blade Motor Power | KW | 3 | 5.5 | 5.5 |

| Blade speed | mt/min. | 15 ÷ 100 | 15÷100 | 15÷90 |

| Motor hydraulic unit | KW | 1.5 | ||

| Tank Capacity of the hydraulic unit | Lt | 50 | 20 | 50 |

| Capacity coolant tank | Lt | 3 | ||

| Dimensions ( B x L x H ) | mm. | 1600x3300x2500 | 2050x3600x2700 | 1950x4000x2750 |

| Height of the work-table | mm. | 900 | 815 | 855 |

| Weight | Kg | 1950 | 3200 | 3600 |

| Type of functioning | Semiautomatic hydraulic | |||

| Suitable for cutting: | Steel / cast iron / high-strength steels / alloys |

Mobile Blade Guide K

On the sawing machines, the mobile blade guide is automatically kept in contact with the cutting point by means of a gas piston. The minimal lubrication is standard , it avoids the dispersion of refrigerant liquid typical in the use of emulsifiable oil, the life of the blade is not in any way affected.

Mobile Blade Guide

On our sawing machines the mobile blade guide is automatically kept in contact with the cutting point.

Safety Wire

As standard the Ktech Saws have a safety system through a wire which in the event of detection of an obstacle or impediment will block the operation in automatic .

Motoreducer and BlockingOn all the saws, with automatic rotation of the saw frame, the rotation takes place via a toothed belt and gear motor , the blocking takes place via the hydraulic cylinder. |

Display Angle KS 702 OPTIONALWith this accessory, which can be requested only for the model with manual rotation, the angle of the sawframe is visualized on an LCD display . It is easy to read, for customers who need to cut at angle. |

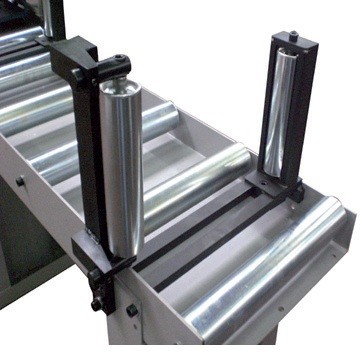

Roller tables KS

Roller tables with freerolls to be used both on loading side and unloading side, with electro-welded steel structure, element of 1,5 meters, support pads and a pedestal. Fitted for the ground fixing and with a possibility of regulation of the height

Roller tables RTL

Roller tables with free rolls to be used on the unloading side, with manual movement, length stop and reading of the measure through LCD display, the length stop slides on balls recirculation guide, available in forms from 3 meters.

Roller tables RTP

Loading-unloading tables with motorized movement of the length stop with the possibility to plan 10 different lengths through PLC . Movement through toothed strap and geared motor on ball recirculation guides . Length stop through pneumatic cylinder. Reading of the position through encoder and rack. Available in forms of 3 meters. Automatic withdrawal of 50 mm to facilitate the unload of the cut piece, return in position through a button on the control.

Vertical Rollers RTSKS

In case that your sawing machine mounts the bundle cutting device, it is advisable to request some vertical containment rollers for the material to be cut.