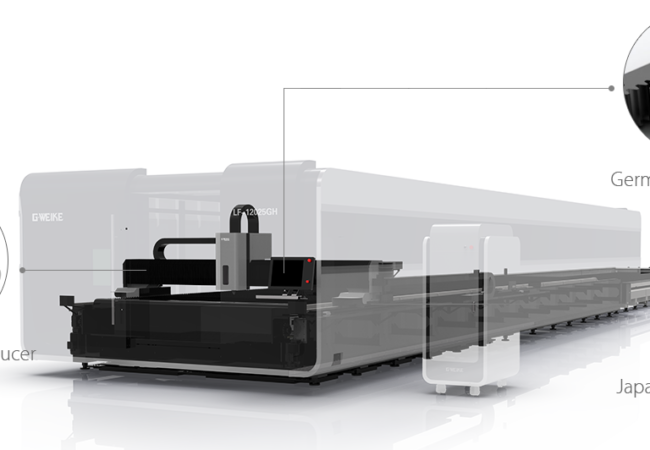

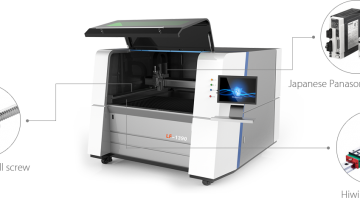

G Weike LF4020GH

Fiber Laser

Installation, operation training, and ongoing support!

G Weike LF4020GH

The LF4020GH is one of the high power GH range of fiber laser cutting machines

The GH range of fiber lasers is specifically designed for high-power fiber laser applications above 3kW. Other GH range of fiber laser models includes LF6025GH, LF10025GH & LF12025GH; More details in the specification section.

- Manufactured with aerospace standards third-generation aviation aluminum gantry

- High strength, stability, and tensile strength, ensuring use without distortion, thanks to the segmented rectangular tube welded bed

- Exchange platform: The Exchange Platform acts as a loading & unloading platform which saves feed time and improves productivity

- A fully enclosed safety design ensures the safety and no smoke

- The Autofocus laser cutting head ensure high efficiency

- Transmission and precision: Fiber laser cutting machine is equipped with a German Atlanta rack, Japanese Yaskawa motor, and German Neugart reducer gear unit.

- Independent Control Cabinet

- The CNC system controller ensures high productivity and simple operation

More Information

SAFETY

- A fully enclosed design;

- The observation window adopts a European CE Standard laser protective glass;

- The smoke produced while cutting can be filtrated inside, it is non-polluting and environmentally friendly;

- The weight of the machine is 7500kg.

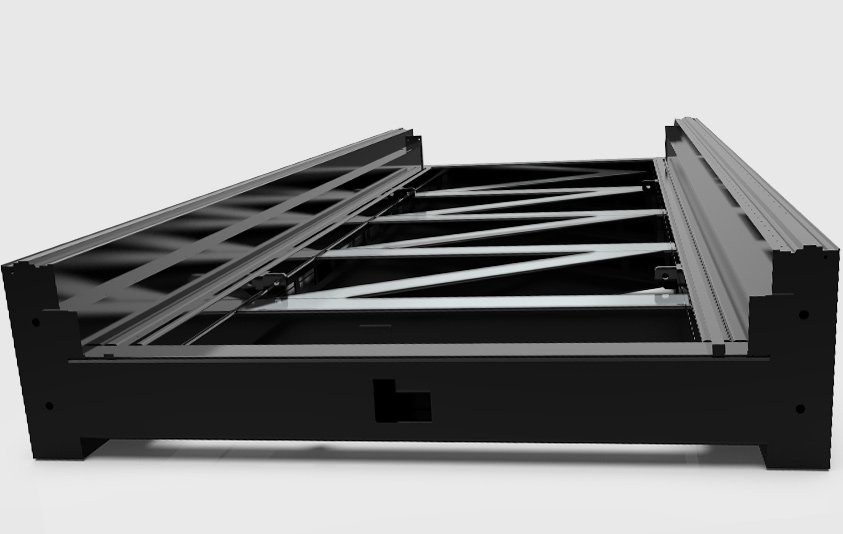

PLATE WELDED- HEAVY WORK BED

- Annealed And Heat Treated

Plate welded heavy work beds, suitable for ultra-high power 10,000-watt laser.

The increase in weight is very beneficial to the laser cutting machine’s cutting speed.

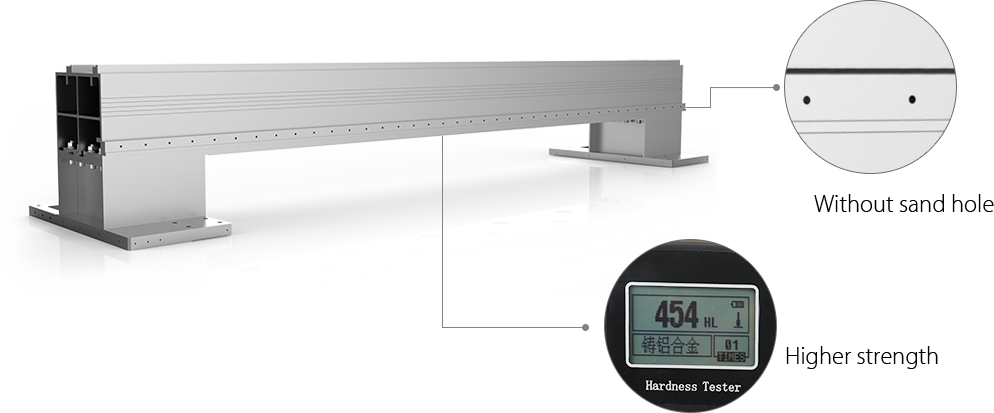

THIRD GENERATION AVIATION ALUMINIUM GANTRY

- Manufactured with aerospace standards and formed by 4300 tons press extrusion molding.

- After aging treatment, its strength can reach 6061 T6 which is the highest strength among all gantries.

- Some of the benefits of Aviation aluminum are:

-High Strength -Light Weight -Corrosion Resistant

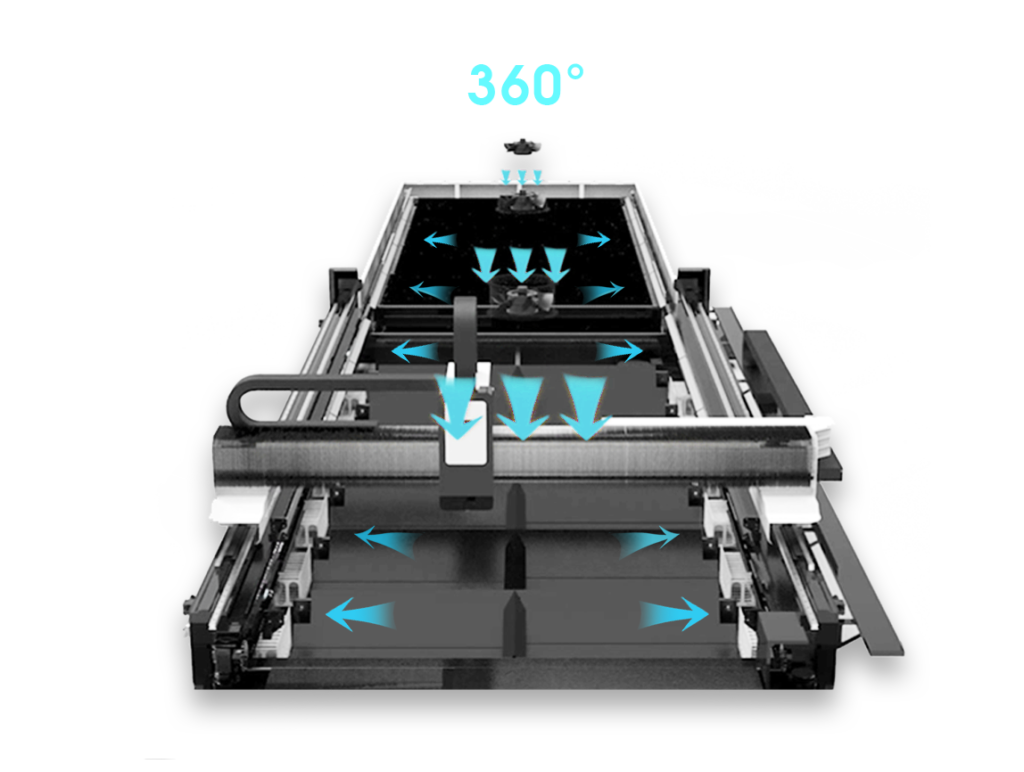

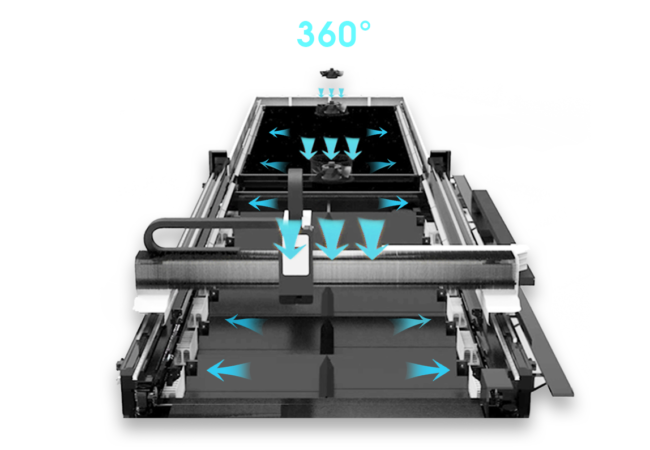

SEGMENTED SMOKE EXHAUST

- Full coverage- super section adopts the latest cutting-edge technology each section of the bed has a smoke exhaust system.

- Powerful negative pressure 360° adsorption axial fan blows smoke downwards creating strong adsorption and consistent smoke exhaust. It effectively purifies the smoke and dust on the top of the enclosed cutting platform and thus reduces lens contamination

- The smoke exhaust device automatically senses the laser cutting position and turns on the precise smoke exhaust.

EXCHANGE PLATFORM

- The Exchange Platform acts as a loading & unloading platform which saves feed time and improves productivity.

- The platform exchange is completed within 15s.

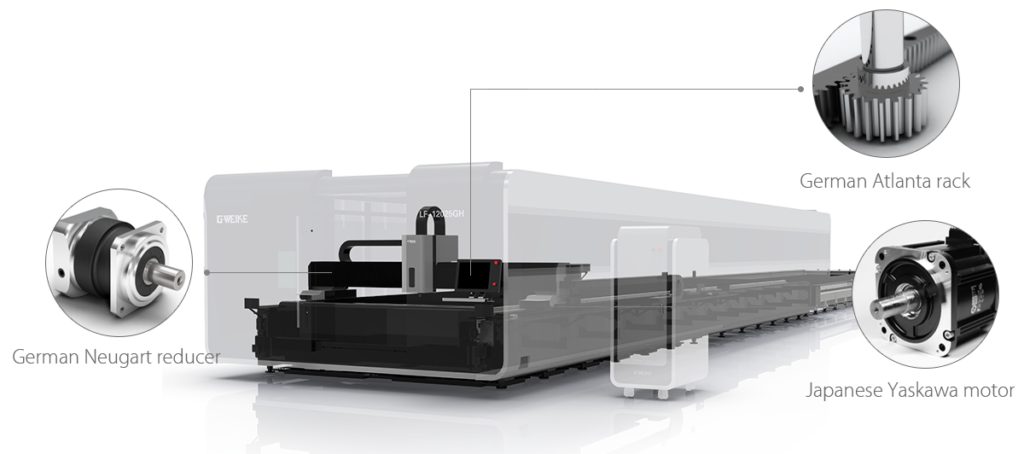

TRANSMISSION AND PRECISION

- The fiber laser cutting machine is equipped with a German Atlanta rack, Japanese Yaskawa motor, and German Neugart reducer gear unit.

- The positioning accuracy of the machine tool is 0.02mm.

- The cutting acceleration is 1.5G.

- Working life is up to 10 years

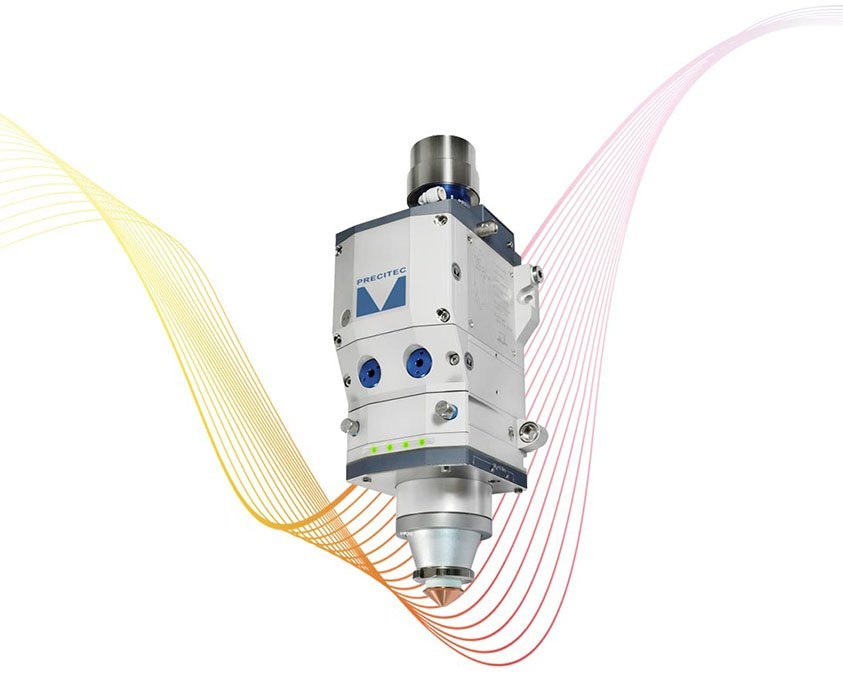

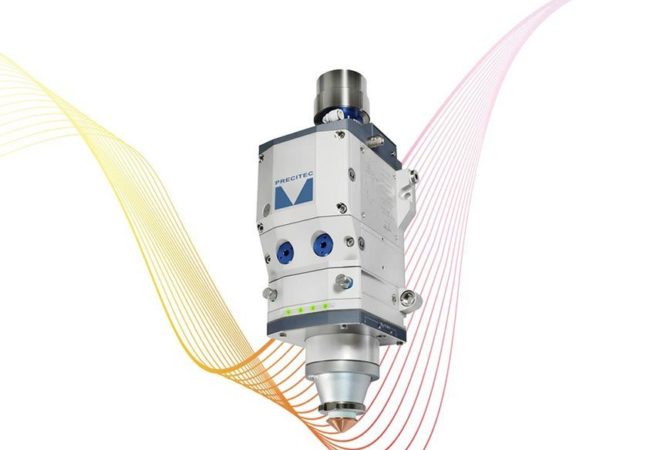

AUTOFOCUS LASER CUTTING HEAD

- Without Manual FocusingThe software automatically adjusts the focusing lens to realize automatic perforating and cutting plates of different thicknesses. The speed of automatically adjusting the focus lens is ten times of the manual adjusting.

- Bigger Adjustment RangeAdjustment range -10 mm~ +10mm, precision 0.01mm, suitable for 0 ~ 20mm different types of plates.

- Long Service LifeThe collimator lens and focus lens both have a water-cooling heat sink which reduces the temperature of the cutting head to improve the life of the cutting head.

CNC OPERATING SYSTEM- FSCUT8000

- FSCUT8000 is EtherCAT bus system designed for ultra high power fiber laser above 8KW, featured by out-of-box service, easy to install and adjust, full solution functions.

- Touch screen controller

- It supports customization, automation, and other great features

- It is the leading edge EtherCAT laser cutting control system on the market.

- The use of high-definition tempered glass, intelligent touch control and fast response speed make the screen more delicate and smooth, and the operation is smoother.

- The CNC system integrates high productivity and simple operation.

- Supports most of the CNC files.

- In-built drawing and nesting tools for simple and quick jobs.

- Different cutting strategies can be applied to the nest.

| Machine model | LF4020GH | LF6025GH | LF10025GH | LF12025GH |

| Laser power | 8000W, 12000W, 15000W, 20000W(Optional) | |||

| Dimensions | 11475 x 2574 x 5169mm | 14937 x 3952 x 2287mm | 22953.5 x 4006 x 2336.5mm | 27092 x 4119 x 2336.5mm |

| Working area | 4000mm x 2000mm | 6000mm x 2500mm | 10000mm x 2500mm | 12000mm x 2500mm |

| Repeat positioning accuracy | ±0.02mm | |||

| Maximum speed | 200m/min | |||

| Max. acceleration | 2.5G | |||

| Voltage and frequency | 380V / 50Hz/60HZ |

THESE ARE THE FOLLOWING OPTIONS AVAILABLE

- LASER POWER SOURCE

- LASER CUTTING HEAD

- COMPRESSOR OPTIONS

- NITROGEN GENERATOR

Recent Comments