CNC Drill

Models: Drill+ 1020 ; Drill+ 1640 ;

Smaller models available as 1,600 x 600 & 2,000 x 600 options.

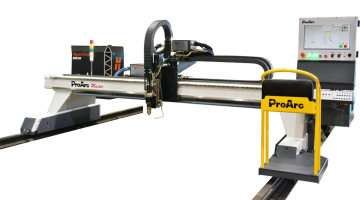

ProArc Drill+

CNC drilling machine – Table type

ProArc Drill+1020, 1640 auto drill machine is an automatic, efficient and high-performance CNC drilling machine.

It constituted of:

1. IPC based CNC controller

2. Servo Z-axis lifter

3. Servo drill spindle

4. Auto tool length detector

5. Auto plate thickness measuring device

It makes the drilling process easy, user-friendly and safe.

More Information

| Model | unit | Drill+1020 | Drill+1640 |

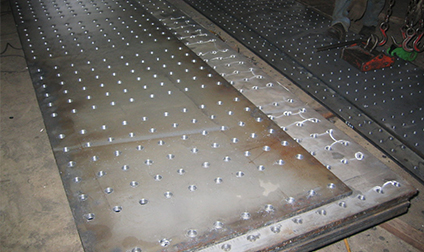

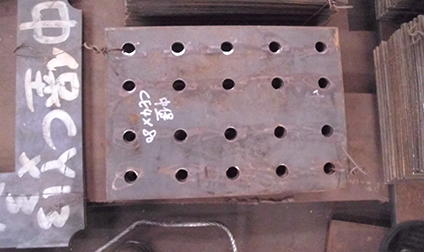

| Table size | mm | 1,000 x 2,000 | 1,6400 x 4,000 |

| Z lifter effective stroke | mm | 350 | 350 |

| Plate thickness | mm | 100 | 100 |

| Positioning accuracy | mm | ±0.1 | ±0.1 |

| Positioning speed | m/min | 16 | 16 |

| Number of spindle | set | 1 | 1~2 |

| Spindle model | Unit | DS-050 | DS-080 |

| Drive motor | hp | 15 | 30 |

| Drilling capacity | mm | Ø6~50 | Ø6~80 |

| Rotation speed | rpm | 10 ~ 2,000 | 10 ~ 2,000 |

| Effective length※1 | mm | 215 ~ 375 | 215 ~ 375 |

| Shank-standard | BT40-MT4 | BT50-MT4 | |

| Shank-tapping (option 1) | BT40-TPM830※3 | BT50-TPM830※2 | |

| Shank-tapping (option 2) | TPC830※3 | TPC830※3 | |

| Shank-indexible drills | BT40-SLA-OD | BT50-SLA-OD※4 |

※1 Effective length: From spindle nose-end to drills end

※2 Shank w/ tapping chuck

※3 Quick change tapping collets

※4 Shank w/side lock holder

AC Servo Z-axis lifter

• Adopt ball screw feeding on Z axis with traveling speed 6,000 mm/min in 350mm stroke and is capable to support precise sequence control for primary, extremity and pecking process for the auto drilling process.

IPC based CNC controller

•Unique and intuitive GUI with touch panel

Build-in Drill+ CAM in the controller

• Can read .dxf file and edit on job site directly

Quick release tool exchange device

• Change tool in seconds

Multi-task process

• Multi-home position can be defined for different jobs and edit in one drilling process

Auto plate thickness detector

• Save measure time and keep accuracy

Crossline laser point unit

• Check position, support plate edge alignment, and tech mode

Teach mode

• Learn parts with multiple drill points and capable to edit drilling process without drawing

Auto tool length detector – one touch

•Save measurement time and keep accuracy