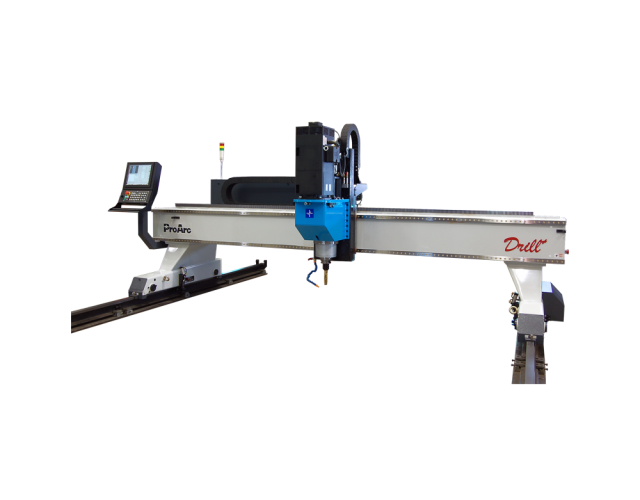

Hugong CNCT – CNC Plasma Cutting Machine

- Steel structure table body to ensure durability and precision.

- Dual driving system on Y, linear bearing, helical rack and pinion drive

- Precision control from Hypertherm Edge Connect digital technology

- 17” touchscreen display, with a functional user interface

- Separate driving system on X-axis with covered linear bearing, rack and pinion

- Electric limits on Y, the machine stops at ends. Safe for machine and operator

- Automatic Hypertherm torch height controller on the Z axis

- Higher speed and high precision capable of MaxPro200, HPR, XPR

- Strong body with air extraction system

- Caution light for operator and machine safety

- Complete Hypertherm shapes library

More Information

| Design and Operation Specification - Air Suction/ Water Table | |

| Plasma power source | Hypertherm Powermax series/HyPerformance plasma |

| Machine structure & operation | Longitudinal drive is via dual drive servos |

| Rail and beams are unique in design & operation | |

| CNCT has strong steel structure which endures long working life | |

| Robust design | |

| CNC controller | Hypertherm Edge Connect Controller |

| CNC monitor | 17" Touch Screen |

| Drive system - Rail- X axis | Dual drive, Panasonic AC Servo motors, 750w |

| Drive system - Transverse- Y axis | Panasonic AC Servo motors, 750w |

| Gear box | Neugart high-performance gear box |

| Rail on X and Y | Linear rails with lubrication system |

| Torch Height Controller (THC) | Automatic THC with Panasonic AC Servo |

| Nesting software | FastCAM CAD CAM Software for Plasma and Oxy. It is a total NC solution for 2D steel shape nesting and cutting; FastCAM allows people at a shop floor level to start profile cutting with the minimum of training. The FastCAM System has been designed to draw, nest and cut metal as simply and efficiently as possible FastCAM can read or convert DXF, DWG, DSTV/NC1, StruCAD, IGES and PDF file formats. Provides additional functions such as Keft compensarion, plasma bridge, common line cutting, CAD layers etc. Ease of use is as important as the high levels of materials utilization and optimization the software provides |

| Dust Extraction | Air suction table/ Water table |

| Parts collection trolley | Included with the machine |

| Bellow covers | |

| Emergency stops | |

| Limit switches | |

| Torch collision retraction system | |

| Laser pointer for easy positioning |

- CNC controller: American, European and Hugong brand options

- Automatic TCH: Hypertherm and Hugong brand options

- Servo Motor: Panasonic

- Gear Box: German Brand Neugart

- Linear Rail: TBI or HIWIN

- Relay: Omron

- Breaker: Schneider

- Nesting Software Options: l Australian: FastCAM PRO l American: SigmaNest American: Hypertherm Turbonest l American: Hypertherm ProNest

| Model | CNCT |

| Power supply(V,Hz) | 230 , 50 |

| Input capacity(KW) | 3 |

| Cutting width(mm)- options | 1500, 2000 |

| Cutting length(mm)- options | 3000, 4000, 5000, 6000 |

| CNC controller- options | Hypertherm or Hugong brand |

| CNC controller | 15''/17'' Touchscreen monitor, USB port |

| Cutting model | Plasma (Flame is optional) |

| Travel speed(mm/min) | 12,000 |

| Accuracy(mm) | Positioning: 0.5/1000, Repeatability: 0.2/1000 |

| Torch height controller (THC) | Automatic THC |

| Plasma options | Powermax series, Maxpro200, HPRXD |

| Nesting software | Optional |

BED OPTIONS

Down Draft

• Zoned downdraft bed for efficient fume extraction

• Easy to remove dross trays for removing scrap metal quickly

• Lift out cutting deck

Water Table

• Water tray for efficient control of sparks and fumes

• Removable stainless steel splash guards for side rail protection

• Large drain and tap for quick and easy emptying

Air Dryer and filter system