T2 Series Tube Cutting Laser Machine

Fiber Laser GKS6024T2

Installation, operation training, and ongoing support!

WORKING T3 SERIES MACHINE IS AVAILABLE FOR VIEWING @ CUSTOMER SITE

(ON REQUEST)

T2 Series Tube Cutting Laser Machine

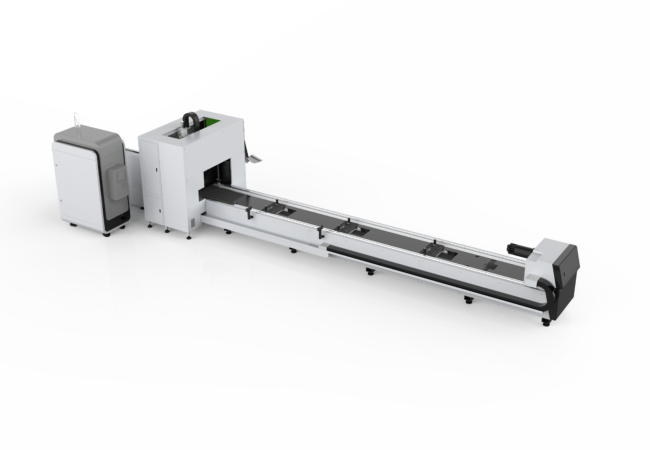

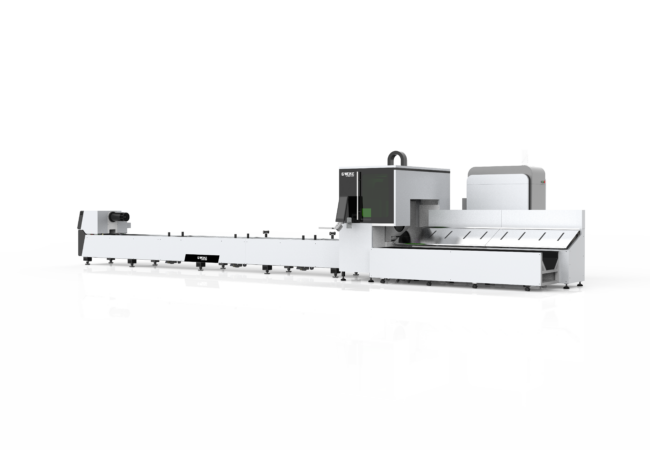

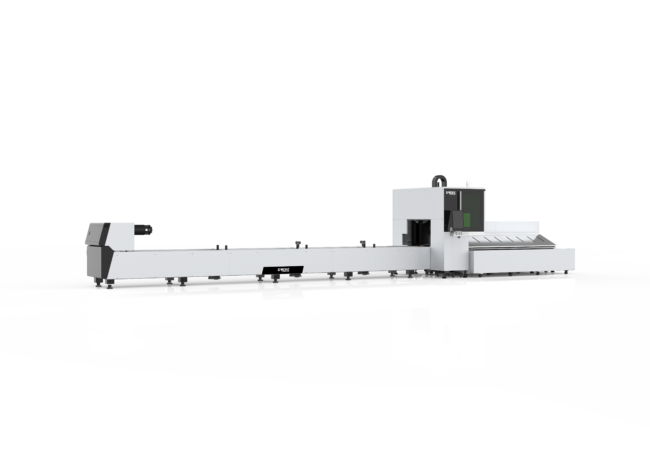

G-Weike Two-Chuck Pipe and Tube Cutting Laser Machine

GKS6024/6036 T2 series Tube Cutting Machine

The G-Weike T2 series pipe and tube cutting laser machine is designed with two chucks and following outfeed sytem.

The product described features several advanced technologies and systems for efficient, high-quality tube and pipe processing. Here’s a summary of the key features:

- Precision Pneumatic Chuck System:

- Supports up to 300kg (6024 model) and 500kg (6036 model) materials.

- Provides a firm grip to reduce material deformation, ensuring accuracy during high-speed cutting.

- Enhanced Cutting Versatility:

- Capable of processing pipes and tubes of various shapes and sizes, maintaining consistent precision for a wide range of materials.

- High-Efficiency Laser Technology:

- Offers clean, smooth cuts with minimal heat-affected zones, making it perfect for industrial applications that require high precision.

- Two-Chuck Configuration with Outfeed:

- Optimizes material handling for tube processing and reduces setup times, enhancing overall efficiency.

- User-Friendly Interface:

- Features intuitive controls and automated functions that make the operation simple, even for less experienced users.

- Infeed Options:

- Offers flexibility with 9-meter and 6-meter infeed lengths, catering to different production requirements.

- Outfeed Options:

- Provides 6-meter and 3-meter outfeed lengths, offering versatility for various production setups.

This combination of features is designed to enhance productivity, reduce material handling time, and ensure high precision and efficiency in tube and pipe processing applications.

More Information

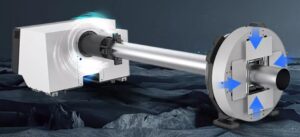

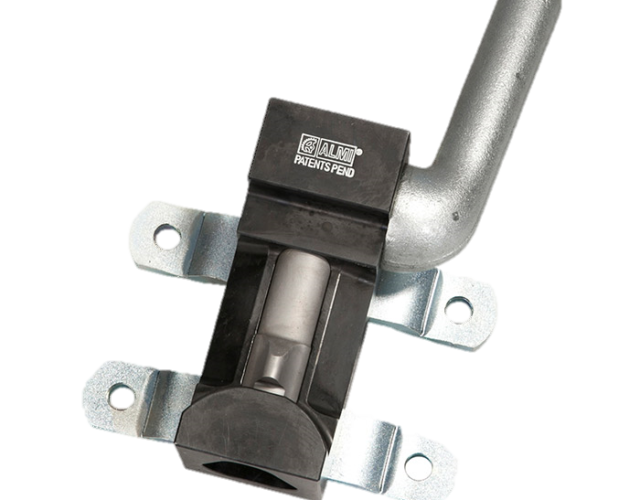

Professional Pneumatic Chuck

Precision pneumatic chuck, four-jaw automatic centering and clamping, stable clamping without damaging the workpiece.

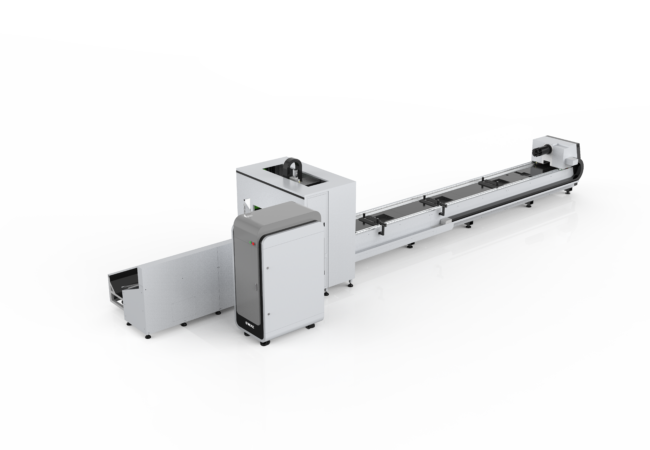

Support arms on the infeed

The tube is supported by the support arm to prevent the tube from sagging and swinging, so as to ensure the cutting accuracy.

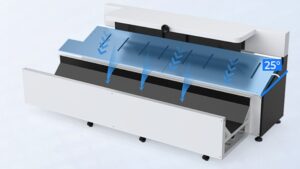

Follow up unloading Rack

Unloading rack with follow up outfeed for material support during cutting

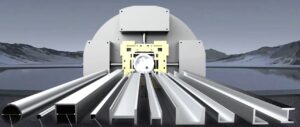

Supports wide range of shapes

Supports cutting of round pipes, square pipes, oval pipes, rectangular pipes, angle steel, channel steel, and various profiled pipes

Samples

| Machine Model | GKS-6024T2 | GKS-6036T2 |

| Laser power | 1500W 2000W 3000W 4000W 6000W | 1500W 2000W 3000W 4000W 6000W |

| Pipe Processing Range | Round pipe:Φ20-240mm; Square pipe:□20-220mm | Round pipe Φ20-350mm Square pipe 口20-250mm I-beams 10#-22# |

| Chuck Max Speed | 100r/min | 60r/min |

| Repeat positioning accuracy | ±0.03mm | TBC |

| Single pipe load-bearing | About 300KG | About 500KG |

| Max tailing length | 200mm | 200mm |

| Maximum Idling speed | 100m/min | TBC |

Recent Comments