Plasma vs Fiber Laser Cutting Machine

Distinguishing Between Plasma and Fiber Laser Cutting Machines: Making the Right Choice for Your Needs

Plasma cutting machines and fiber laser cutting machines are both used for cutting various types of materials, but they have different operating principles and advantages. Here’s a comparison of the two:

-

Operating Principle:

Plasma Machine: Plasma cutting uses a high-temperature, ionized gas (plasma) to melt through the material. An electrical arc is created between an electrode and the workpiece, which ionizes the gas and generates a focused jet of plasma to cut through the material.

Fiber Laser Machine: Fiber laser cutting uses a high-power laser beam generated within a fiber optic cable. The laser beam is focused and directed onto the material’s surface, which causes it to melt or vaporize, cutting through the material.

-

Cutting Speed:

Plasma Machine: Plasma cutting is generally faster than some other cutting methods like oxyfuel, but it may be slower compared to fiber laser cutting, especially when cutting thin materials.

Fiber Laser Machine: Fiber laser cutting is known for its high cutting speed, particularly when working with thin to medium-thickness materials.

-

Precision and Accuracy:

Plasma Machine: Plasma cutting is precise for many applications but may have slightly wider kerf (cut width) compared to fiber laser cutting. It may not be as suitable for intricate and fine detailing.

Fiber Laser Machine: Fiber lasers offer exceptional precision and accuracy. They produce narrower kerfs and are capable of intricate and detailed cutting, making them ideal for various industries, including aerospace and electronics.

-

Material Compatibility:

Plasma Machine: Plasma cutting can handle a wide range of materials, including steel, stainless steel, aluminum, and non-ferrous metals. It is also suitable for cutting thicker materials.

Fiber Laser Machine: Fiber laser cutting excels at cutting thin to medium-thickness materials, especially metals like steel, stainless steel, aluminum, and brass. It is less effective for very thick materials.

-

Maintenance and Operating Costs:

Plasma Machine: Plasma cutting systems generally have lower upfront costs but can have higher operating costs due to consumables like electrodes and nozzles that need replacement.

Fiber Laser Machine: Fiber laser machines have higher initial costs but tend to have lower operating costs and longer lifespans because they have fewer consumables and require less maintenance.

-

Environmental Impact:

Plasma Machine: Plasma cutting can produce more smoke, fumes, and noise compared to fiber laser cutting, making it less environmentally friendly.

Fiber Laser Machine: Fiber laser cutting is cleaner and more environmentally friendly, as it produces minimal emissions and noise.

In summary, the choice between a plasma cutting machine and a fiber laser cutting machine depends on your specific application requirements, budget, and the materials you intend to work with. Plasma cutting is more cost-effective for thicker materials, while fiber laser cutting offers superior precision and speed for thinner materials and intricate designs.

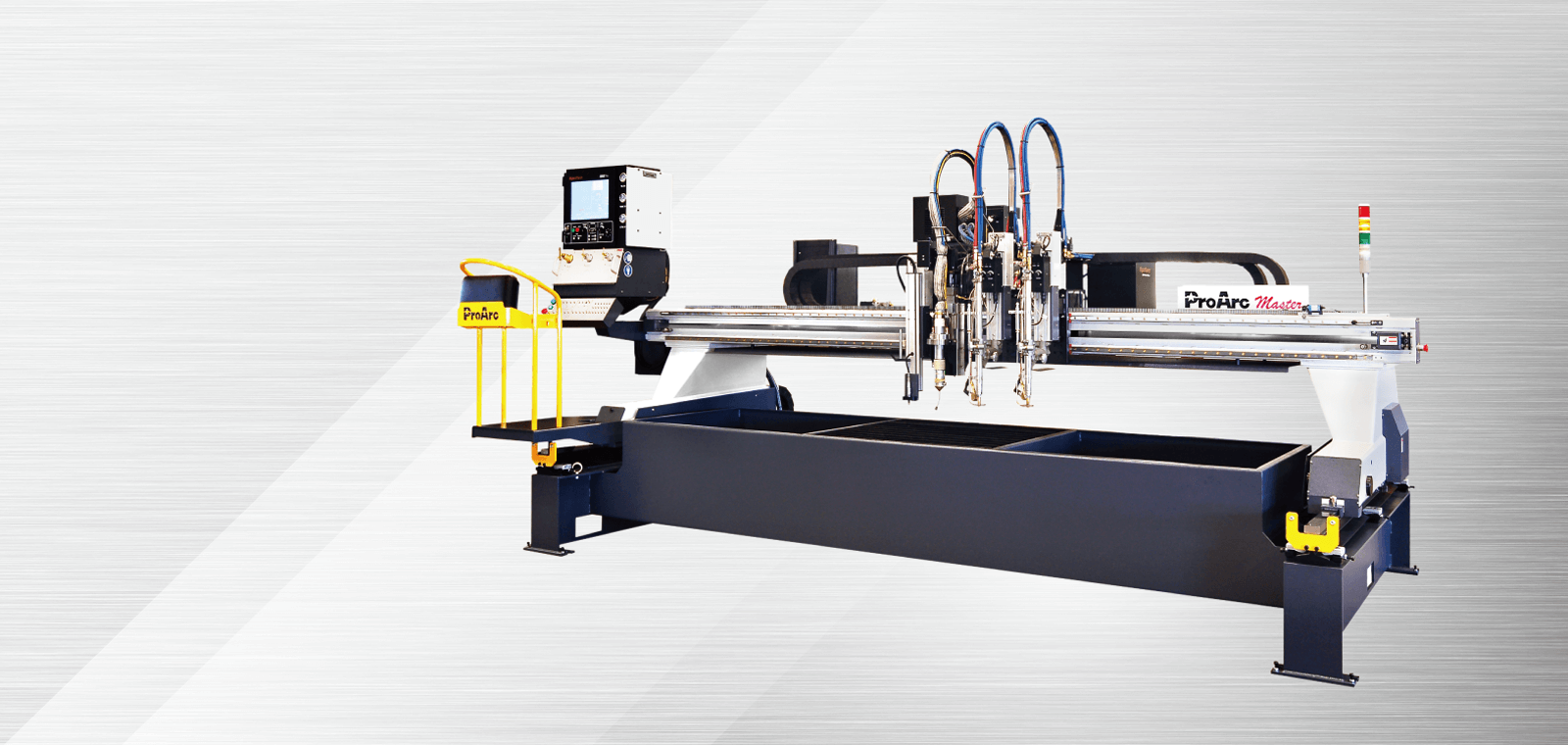

Contact us to find out more about our Plasma and Fiber Laser machine range.