HIGHEST PROFITABILITY & PRODUCTIVITY

More flexible and more productive than ever! (Suited for upside-down bevels)

Plate and tube beveler Cevisa CHP 12

The CHP 12 INV can bevel in an upside-down position effortlessly in a complete self-feed mode. As its emblematic model the CHP 12, the beveler CHP 12 INV is the perfect solution to bevel largediameter tubes as well as tankheads, thanks to its breathing valves.

Its bevelling speed makes this machine the most high performance and flexible beveling system of all the CHP 12 range for large plates and diameter tube bevelling, simplifying production processes as much as possible and reducing production time.

Benefits of standard shearing cutting bevelling machine CHP 12 INV

- Flexible: breathing valve to change position easily.

- High profitability: high speed self-feed bevel -2,6 m/min.

- Constant and uniform bevel depth + high bevel capacity up to 17 mm bevel.

- Dry cut: no need to prepare plates and tubes to bevel.

More Information

Performances

- Speed: 2.6 m/min

- Maximum bevel in one run: 12 mm*

- Maximum bevel recommended in several runs: 17 mm*

- Maximum recommended thickness: plates and tubes up to 20 mm

- Nominal thickness: plates and tubes from 6 mm to 40 mm

- Double bevel with 2 machines working in parallel: CHP 12 + CHP12 INV

- Plate beveling: width min. 55 mm (for smaller width, please consult)

- Tube bevelling: Ø min. int.100 mm

- Disc bevelling: Ø min. 350 mm

* Dimensions calculated on 400 Mpa steel, bevel length

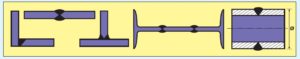

Bevel blueprint

Plate bevelling: K, V, X and Y bevels

Pipe bevelling: vertical or horizontal position – K, V, X and Y bevels, on the inside or the outside of the tube (depending on diameters).

Bevel speed: 2.6 m/ min

Specifications

Motor: three-phase

Motor power: 3 CV – 2.2 kW

Voltage:

- 220/380 V. 50 Hz.

- 250/440 V. 60 Hz.

- For other voltages, please consult us

Electric box with:

- Thermomagnetic switch trip

- Emergency stop button

Net weight: 65 Kg

Works height: adjustable

Reversing switch