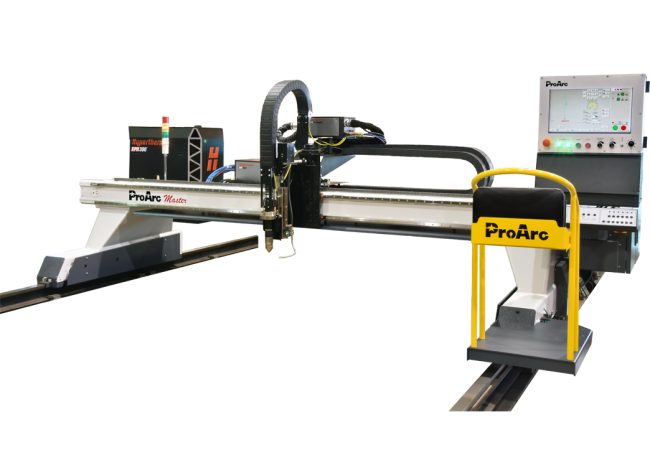

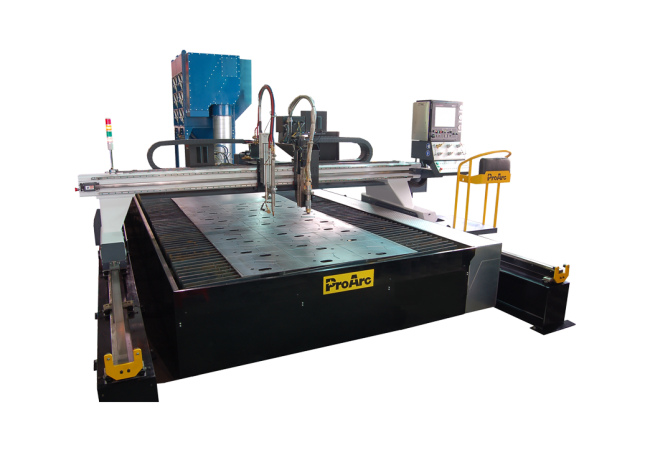

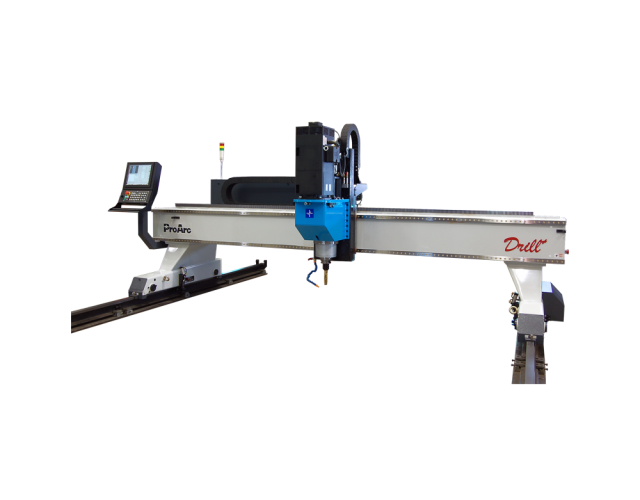

ProArc Master Series- Gantry CNC Plasma and Oxy Cutting Machine

ProArc Master series is a versatile and reliable gantry cutting machine. Master series is designed to be a stable and cost-effective product to meet the needs of all cutting sizes. It enables every business to be more productive with plasma and oxyfuel cutting systems. ProArc Master is a high-performance machine for quality production cutting.

More Information

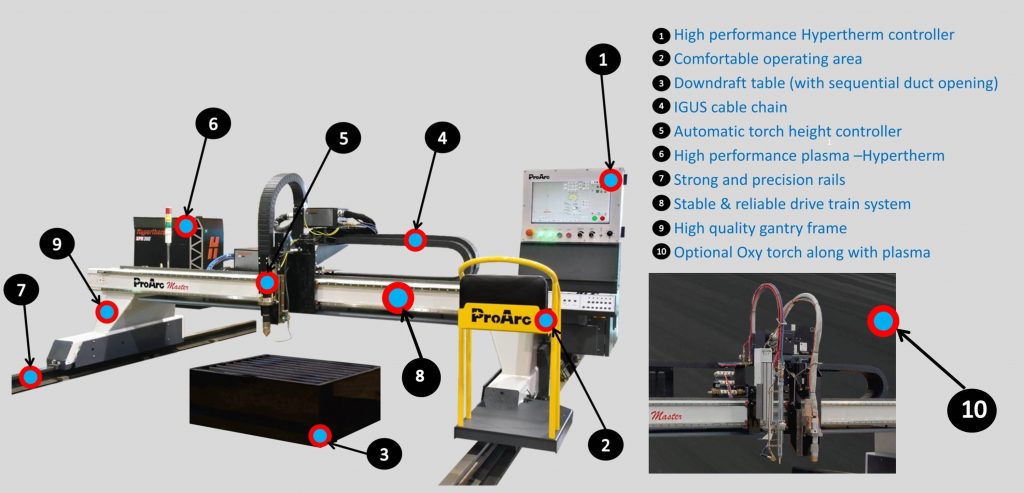

- Rigid structure

- Advanced CNC Controller

- Built with operator platform

Flip down chair design suitable for production and maximize operation space - Accuracy

-±0.1mm - Precision linear way

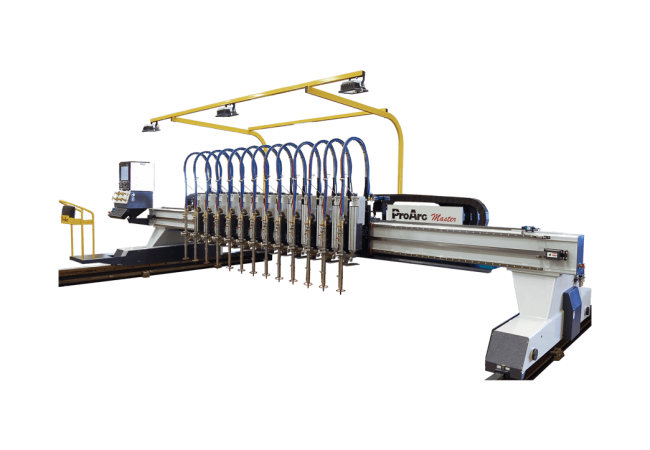

With copper cover for durable lifetime - Torch Station

Maximum: 1 Plasma + 6 Oxyfuel torch - Rail

37kg/m precision grinding I-rail

3M per section - Gas control system for Oxyfuel cutting

High pressure copper pipes

Long life and safe - Sealed cable chain for better protection

- High performance control system

- Reliable gas distribution system

- Comfortable operating area

- Ease of use

- Safe operation

- Clean operating environment

Sequential extraction system

| Model | Unit | Master 20s/20 | Master 25s/25 | Master 30s/30 | Master 35s/35 | Master 40s/40 |

|---|---|---|---|---|---|---|

| Power input | V,Hz | AC 220V, 50 ,3 phase | ||||

| Travel drive method | Rack & Pinion | |||||

| Longitudinal rail | Grinding l-rail | |||||

| Transverse rail | Double linear way | |||||

| Overall width (A) | mm | 3000 | 3500 | 4000 | 4500 | 5000 |

| Overall height (B) | mm | 1950 | 1950 | 1950 | 1950 | 1950 |

| Overall depth (C) | mm | 1500 | 1500 | 1500 | 1500 | 1500 |

| Cutting width (D) | mm | 1600 | 2100 | 2600 | 3100 | 3600 |

| Rail gauge (E) | mm | 2000 | 2500 | 3000 | 3500 | 4000 |

| Parking space | mm | 1500 | 1500 | 1500 | 1500 | 1500 |

| Cutting speed | m/min | 8/12/16 | ||||

| Traveling speed | m/min | 12/16/24 | ||||

| Min. distance between 2 torches | mm | 100 | ||||

| ※1 Master 20s / 25s / 30s / 35s / 40s is single drive on longitudinal axis | ||||||

| ※ Specifications subject to change without notice |