DRILLING – FLAT BAR – MARKING – PUNCHING – SHEARING – SPOTTING – ANGLES

Geka Alfa 500 series

The ALFA product line is designed for automated punching, marking and shearing of flat bars. Alfa 500/150 can punch angle bar. This yields a final product in one single process, significantly increasing productivity, maximizing efficiency, and dramatically reducing cost and downtime. ALFA is the ideal choice for steel truss construction, bridge building, manufacturing of electric power transmission equipment, steel fabricators, marine metal fabrication, for high-volume flat bar processing and angle.

More Information

Capacities based on a material resistance of 45 Kg/mm2. Technical characteristics valid except for typographical errors or omissions. Geka group, committed to continuous product improvement, may without notice change technical specifications, equipment, and photographs of models, as well as any other information contained herein.

| ALFA 500/150 | |

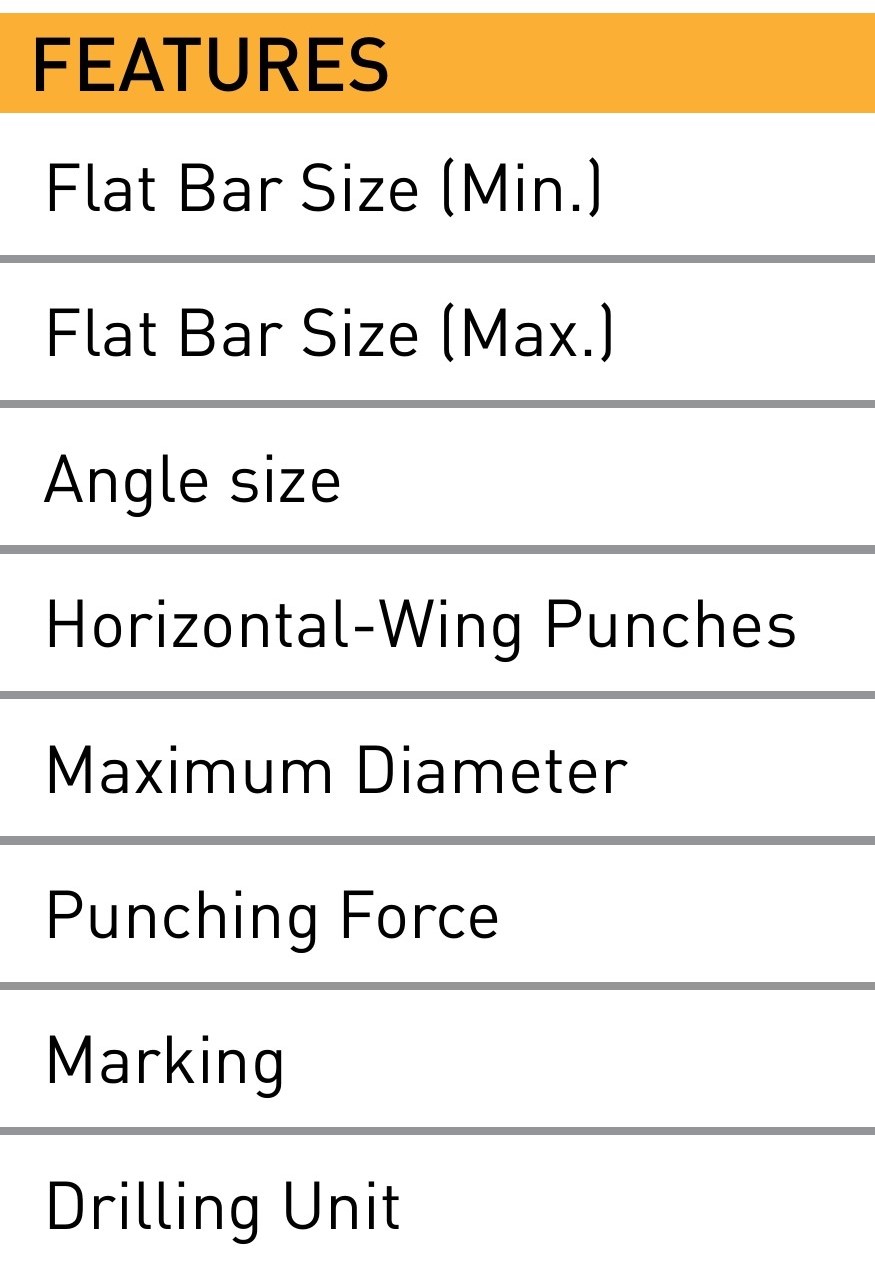

| FEATURES | |

| Flat Bar Size (Min.) | 50x5 mm |

| Flat Bar Size (Max.) | 500x20 mm |

| Horizontal-Wing Punches | 3 |

| Maximum Diameter | 40 mm |

| Punching Force | 1100 kn |

| Marking | Disc |

| Number of characters | 40 |

| Vertical wing punches | 1 |

| Maximum Diameter | 31 mm |

| Vertical Punching Force | 600 kn |

| Angle Processing (Min. Size) | 40x40x4 mm |

| Angle Processing (Max. Size) | 150x150x15 mm |

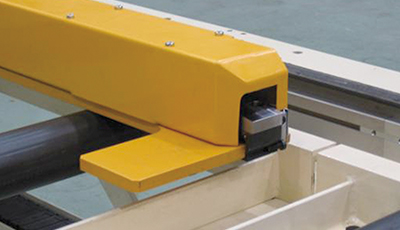

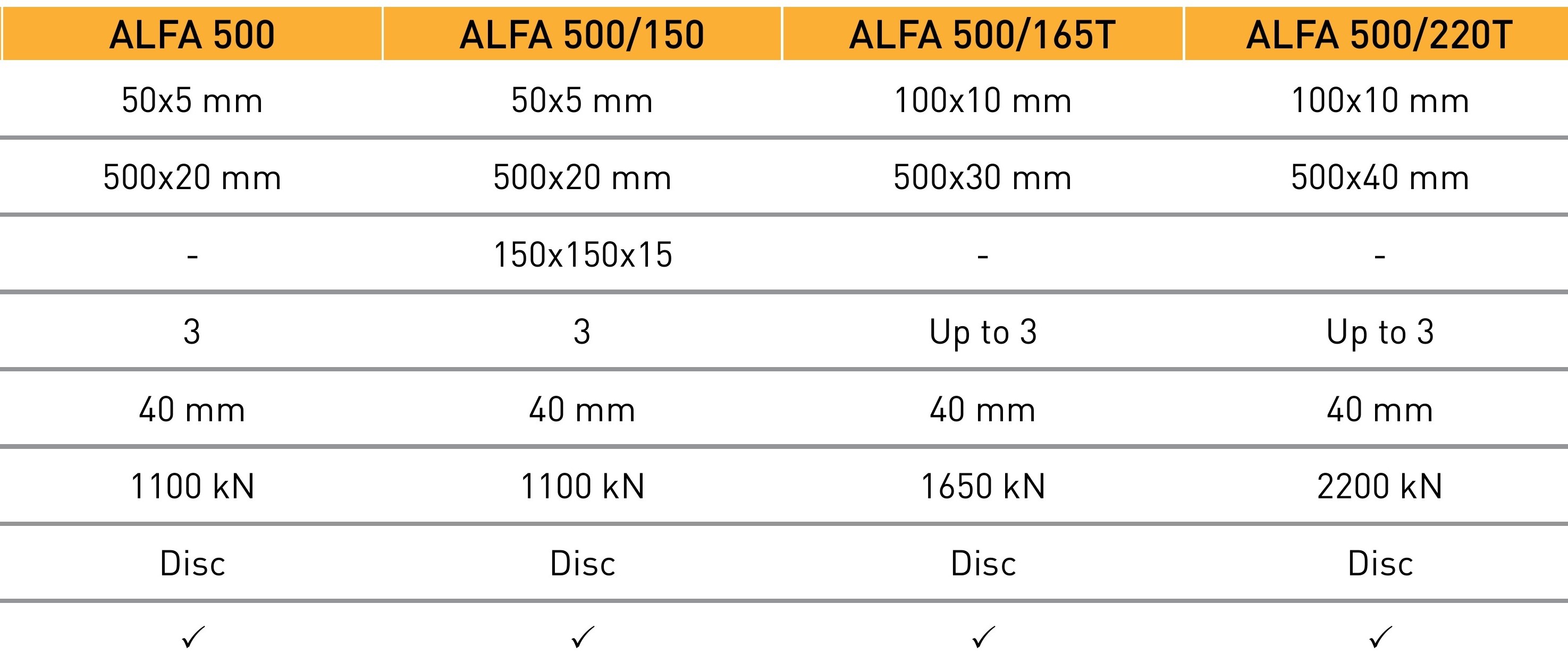

INPUT CONVEYOR UNIT

INPUT CONVEYOR UNIT

- Rack & pinion servo drive carriage

- Flat bars and angles are pushed and clamped by the carriage

- Pneumatic clamping guides

- Side rollers

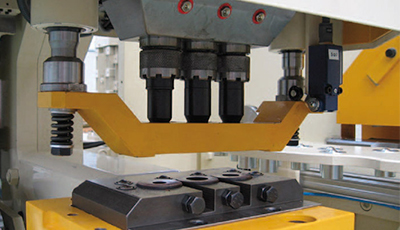

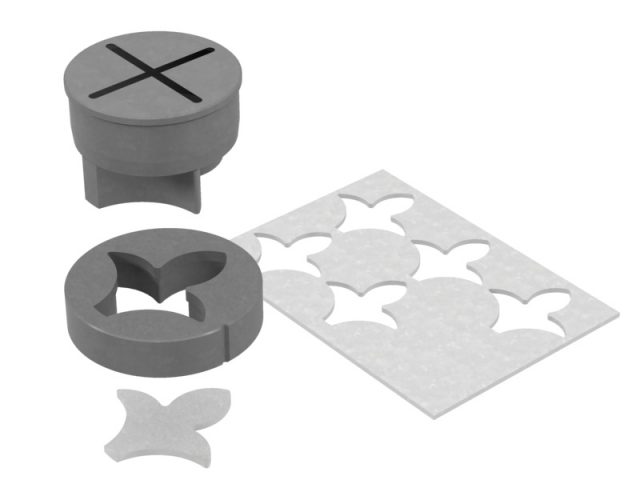

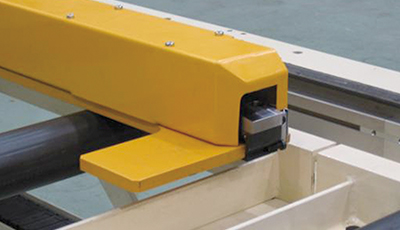

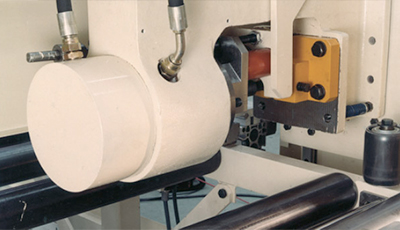

HORIZONTAL-WING PUNCHING UNIT

- Accommodates three different, independently-selectable punches

- Diameter up to 1 9/16″

- Hydraulic hold down

- Servo motor and spindle-driven horizontal positioning along Y-Axis

VERTICAL-WING PUNCHING UNIT

- Single punch unit

- Diameters up to 1 1/4″

- Hydraulic hold down

- Hydraulic servo valve control and spindle-driven vertical positioning

SHEARING UNIT

- Flat bar cuts

- Steel angle cuts

- Hydraulic clamping guides

- The only one-station system for flat bar and angle shearing

- Patented system

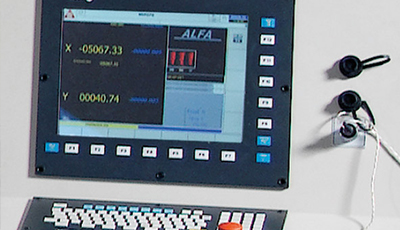

USER-INTERFACE

- PC on Windows platform

- Network Connectivity

- USB ports

- Graphic interfaces

- Remote Assistance via internet

AUTOMATED FEEDER

- Handles steel profiles up to 40′ in length

- CNC-controlled

VERTICAL DRILLING UNIT

- 40mm maximum diameter

- ISO /SK 40 Tool Holder

MITRE SHEAR UNIT

- Mitre shearing of flat bars from – 45 to 45º

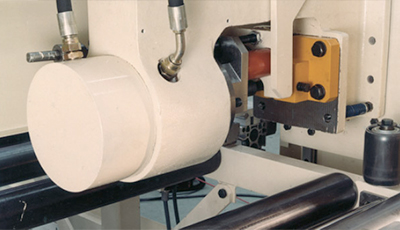

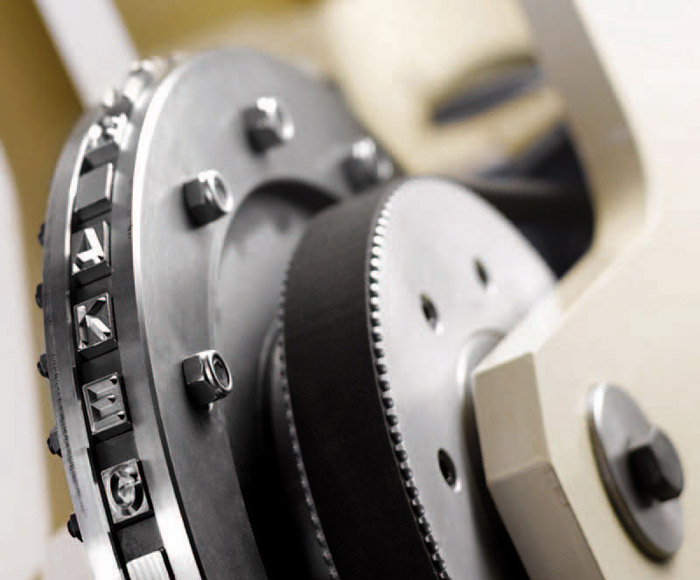

MARKING UNIT

- Disc type

- Accommodates up to 40 characters

- CNC-Controlled

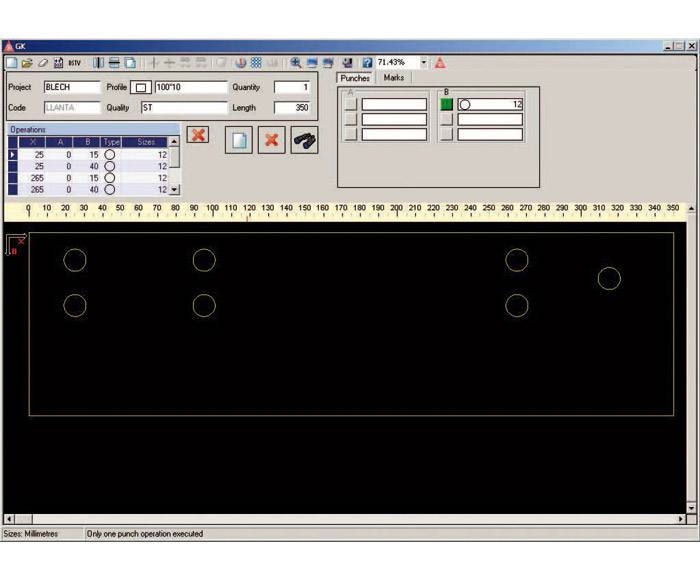

LINE PRO Software

- Importing of .dxf and .dstv files

- Nesting optimizes material use