Horizontal Hydraulic Press Brake PP200CNC

Horizontal Hydraulic Press Brake PP200CNC

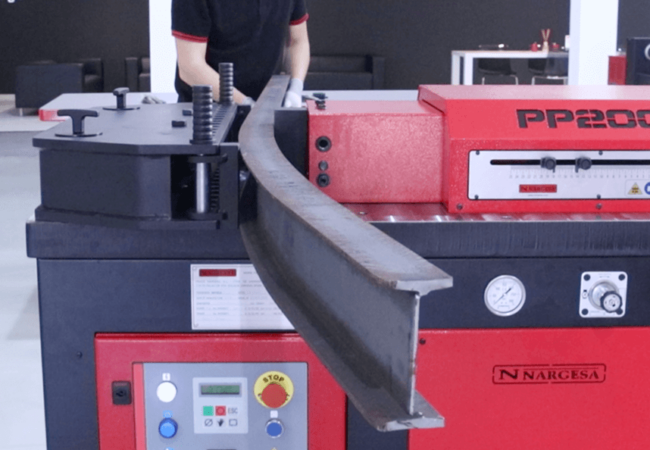

BRAND NEW 20 ton Nargesa PP200CNC Horizontal Press Brake. Includes CNC Control Panel with the latest 4.0 technology, for a more comfortable and accurate regulation. It allows us to carry out different operations such as bending, folding, cutting, cold shaping, expand and reduce tubes, notching, inlaying, assemble… with maximum precision and speed

Horizontal Hydraulic Press Brake PP200CNC

-

-

Easy handling: The machine is sent completely assembled, it is only necessary to connect it to the required power supply and start performing.

-

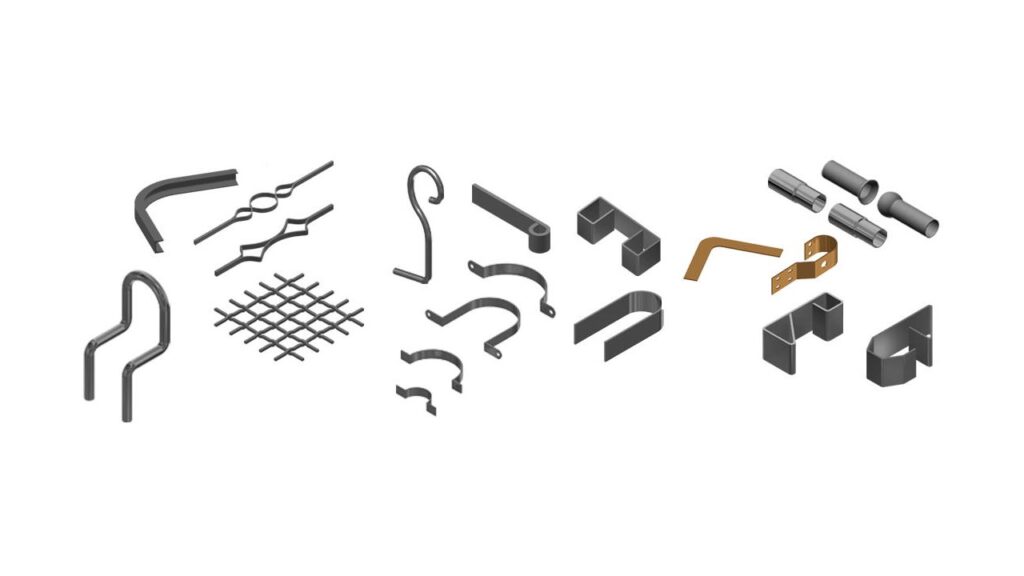

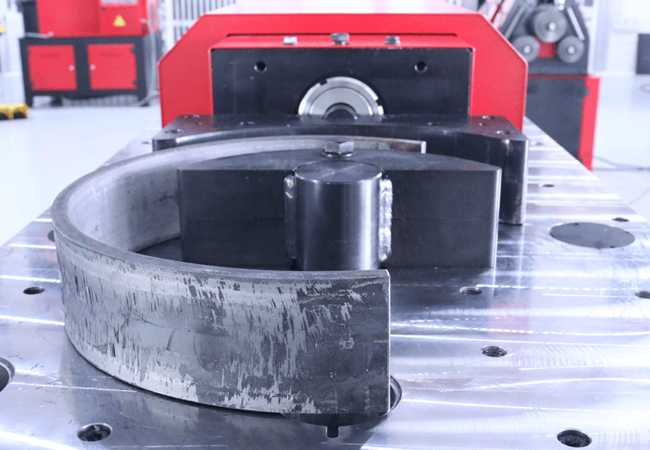

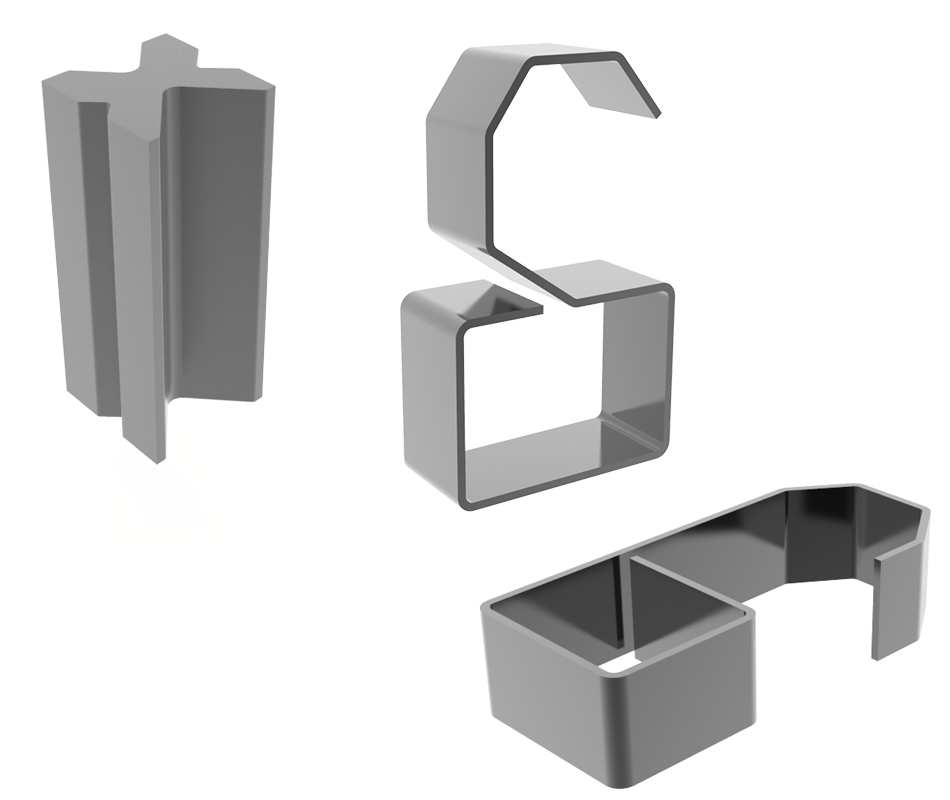

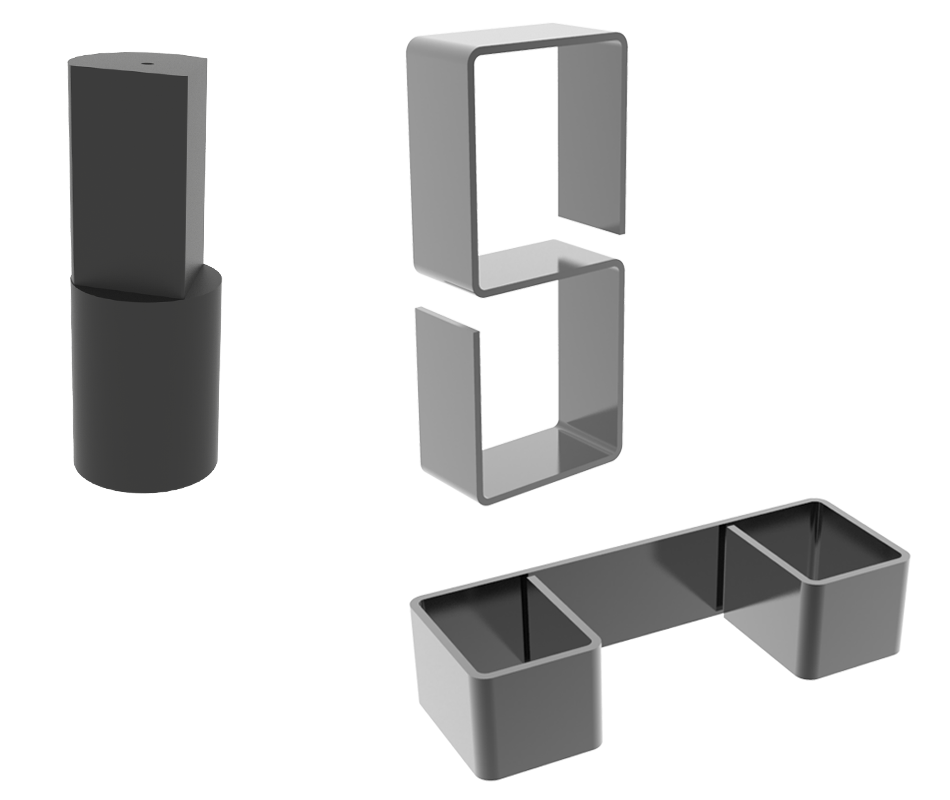

Versatility: Nargesa PP200CNC has a catalog with a great deal of optional tooling.

-

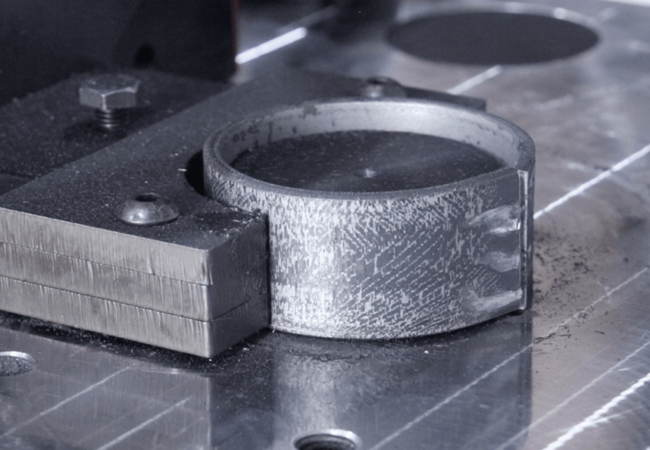

Easy fabrication of tooling: The customer himself or any toolmaker can manufacture dies and punches.

-

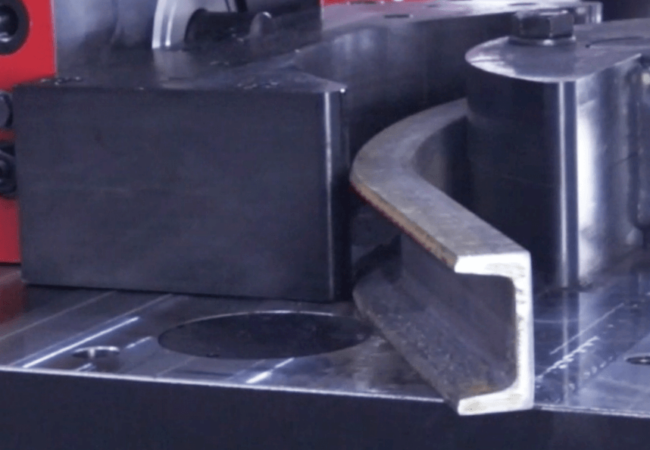

Folding operation with no risk of damaging the punches and dies with thick materials unlike conventional press brakes.

-

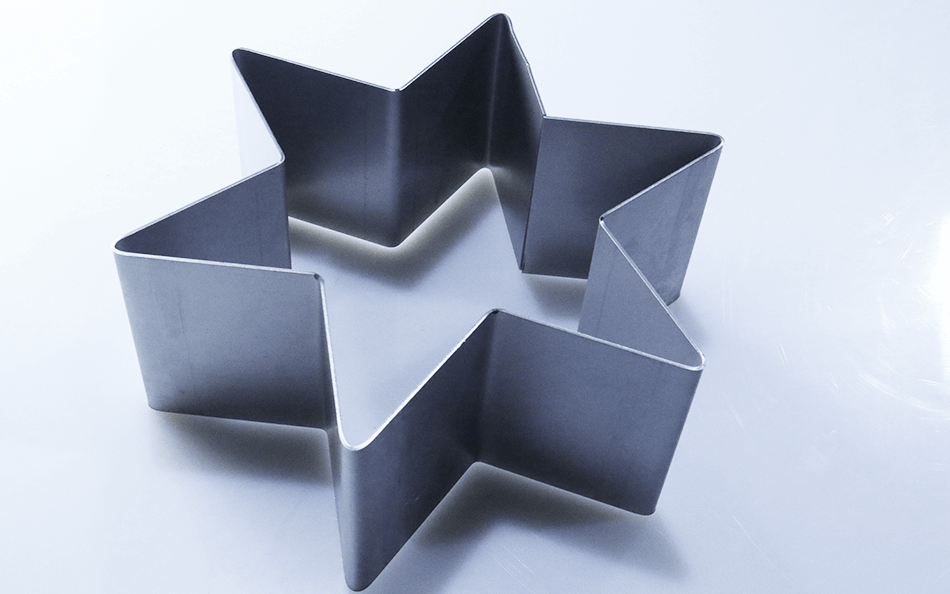

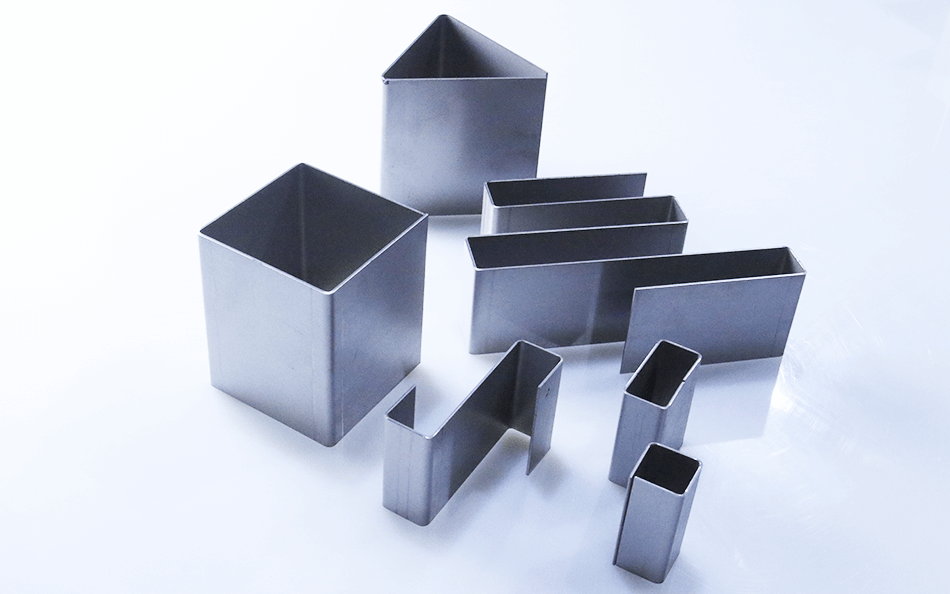

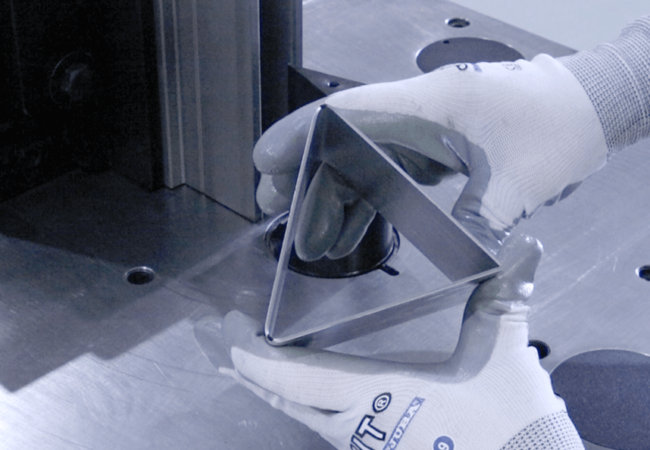

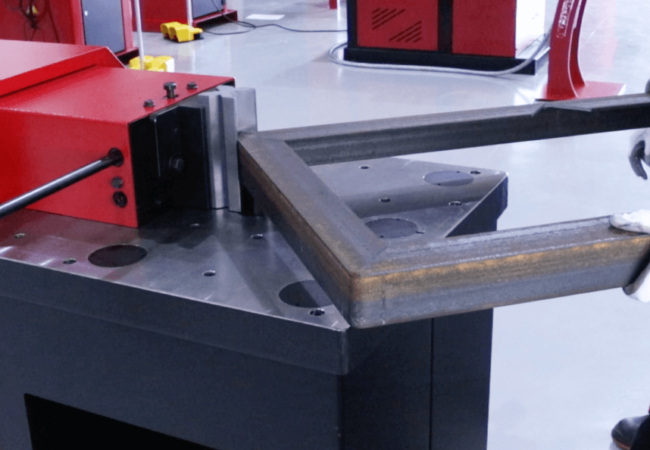

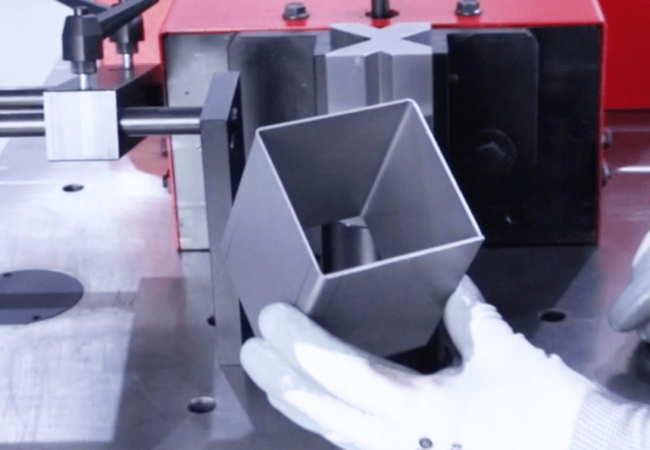

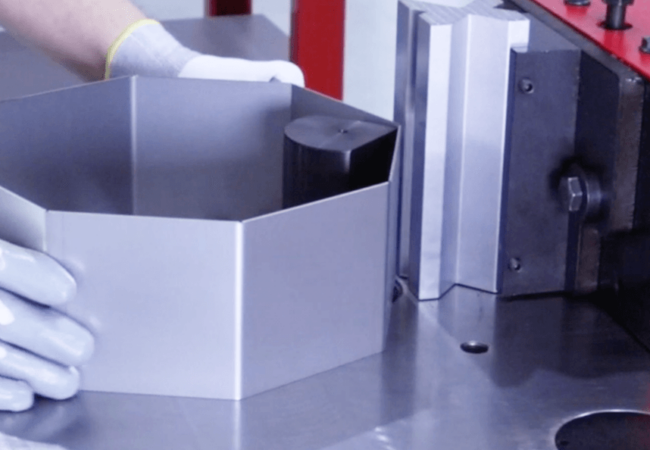

Folding flat bars and sheets into completely close shapes. Conception of this horizontal bending press brake allows to make folding operations that are impossible to be carried out on a conventional press brake.

-

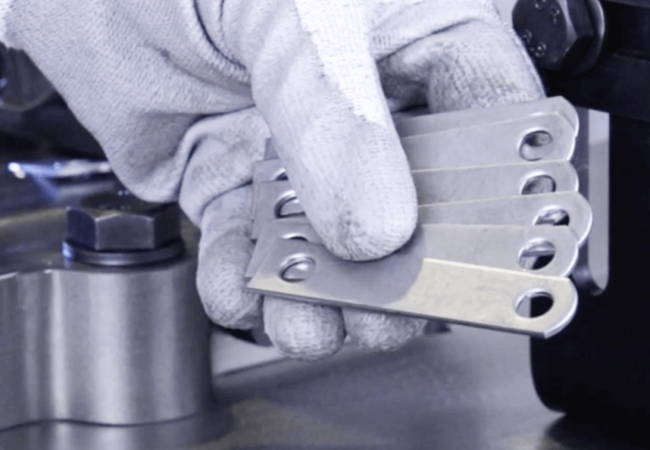

Fast tool change, punches and dies: This change does not take more than 30 seconds most of the times.

-

More Information

STANDARD EQUIPMENT PROVIDED WITH THE MACHINE

- Horizontal press brake PP200CNC includes the complete 4V’s folding die.

- Folding operation with no risk of damaging the punches and dies with thick materials unlike conventional press brakes.

- Folding flat bars and sheets into completely close shapes. Conception of this horizontal bending press brake allows to make folding operations impossible to be carried out on a conventional press brake.

- Fast tool change, punches and dies: This change does not take more than 30 seconds most of the times.

- A set of punch and folding die is supplied along with the machine.

- Performance by a safety double activation hold pedal.

- Low noise level, improving the quality of work of the operator.

- The machine is shipped completely assembled and ready to work.

- Palletized lower bench to easily transport the machine up to its working or storage site.

- Dies support shelf included.

- Lateral stop to place it right or left.

- All our products are manufactured in our facilities in Spain. Hydraulic and electrical components are all standard from the best leading European trademarks with technical support all over the world: Rexroth, Bosch, Roquet, Schneider Electric, LG, Telemecanique, Pizzato…

| ESA S625 CNC control Technology 4.0. |

| Storage of up to 10,000 programs |

| Programming of 50 different angles in the same piece |

| Programming in mm or inches |

| Library of dies and punches |

| Programming in more than 20 languages |

| Automatic control of angle to fold in degrees |

| Manual or automatic operating mode |

| Automatic springback correction |

| Counter of pieces |

| Diagnosis of alarms on the screen |

| Automatic warning of preventive maintenance |

| Remote connection included |

| 7" color touch screen |

| Safety Double acting hold pedal |

| Mechanically Guided Piston |

| Pressure regulator |

| Machine Specification - PP200 | |

| Working force | 20 Ton. (200KN) |

| Working speed | 9.8 mm/s |

| Return speed | 35 mm/s |

| Max stroke | 245 mm |

| Repeatability | 0.05 mm |

| ECO mode | Start/Stop in period of inactivity |

| Tooling support table | 600x1170 mm |

| Working height | 950 mm |

| Engine power | 2.2 KW/3 HP a 1400 r.p.m |

| Electric Tension | 230/400 V three-phased |

| Intensity | 9/5 A |

| Hydraulic pump | 7.5 litres/minute |

| Tank Capacity | 27 litres |

| Machine Dimensions | 660 x 1,180 x 1,130 mm |

| Machine Weight | 665 kg |

ADVANTAGES

- NEW Control Panel: Very intuitive and easy to handle, with the latest 4.0 technology and a more comfortable and accurate regulation.

- The new ECO mode of our latest products saves energy and contributes to the conservation of the environment.

Nowadays, we know the remarkable importance of saving energy. This is the main reason why our new machinery incorporates an “ECO mode” that automatically disconnects the electrical parts that generate greater energy consumption if a period of inactivity is detected. Thus, when it is necessary to restart the operation, all you have to do is press the pedal to continue working.

We strongly believe that this feature is a core point both for the savings of our clients and for the sustainability of our planet, since we are a company very committed to the environment. - Quick start-up: The machine is shipped fully assembled, it is only required to connect it to the electrical supply and run it.

- Versatility: Nargesa PP200 has a catalog with a great deal of optional tooling. (See at the bottom of the page in optional tooling and sample video).

- Easy fabrication of tooling: The customer himself or any toolmaker can manufacture dies and punches.

- Folding operation with no risk of damaging the punches and dies with thick materials unlike conventional press brakes.

- Folding flat bars and sheets into completely close shapes. Conception of this horizontal bending press brake allows to make folding operations impossible to be carried out on a conventional press brake.

- Fast tool change, punches and dies: This change does not take more than 30 seconds most of the times.

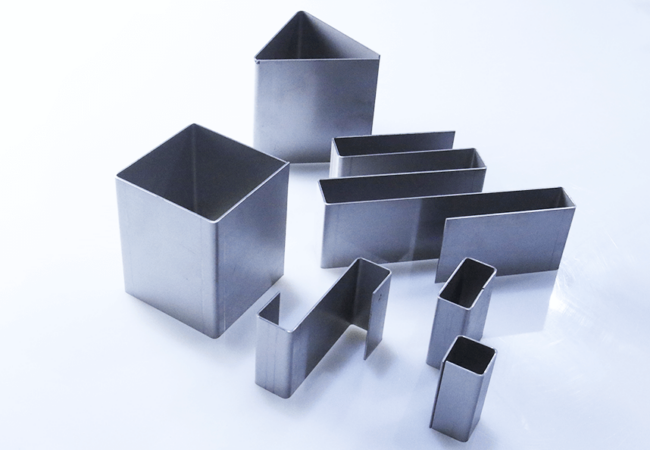

Samples

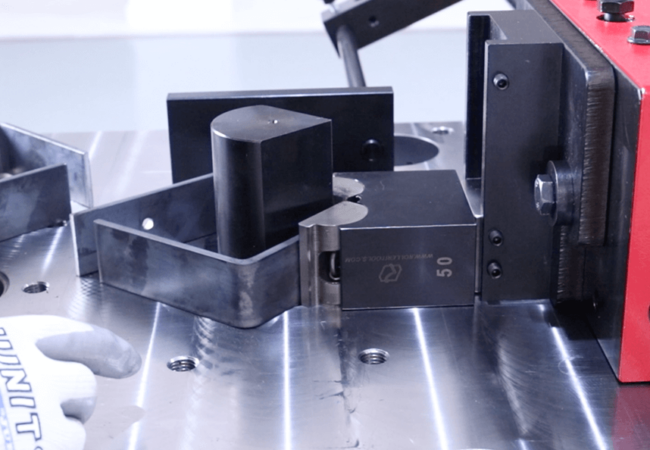

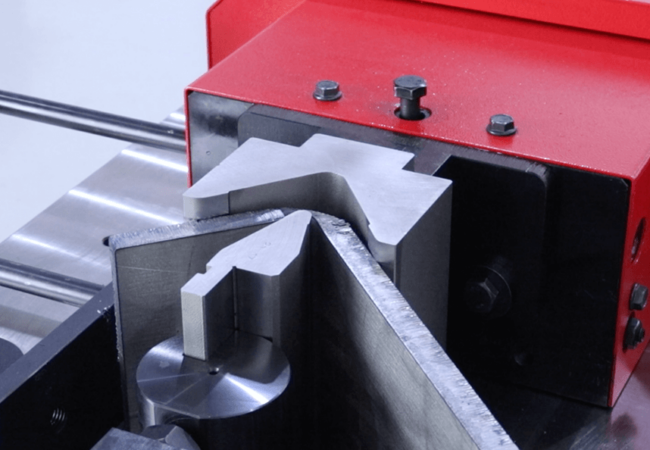

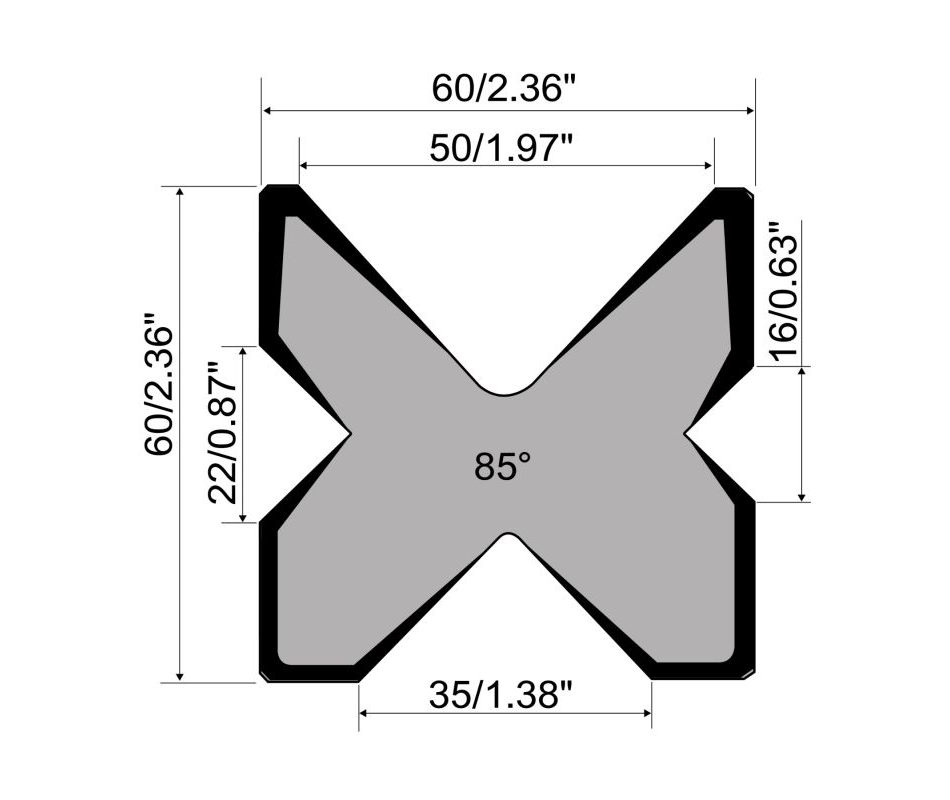

FOLDING DIE AT 161 mm. V 16,22,35,50 mm

Bending die for up to 161 mm with 4 openings (16, 22, 35, 50 mm). This multi-V die allows bending sheet metal from 1 mm to 8 mm.

Reference: 125-16-01-00006

V 16: Sheet metal from 1 to 3 mm · M.460.R/16

V 22: Sheet metal from 2 to 4 mm · M.460.R/22

V 35: Sheet metal from 3 to 6 mm · M.460.R/35

V 50: Sheet metal from 4 to 8 mm · M.460.R/50

MAXIMUM BENDING LENGTH: 161 mm

MAXIMUM BENDING THICKNESS: 8 mm

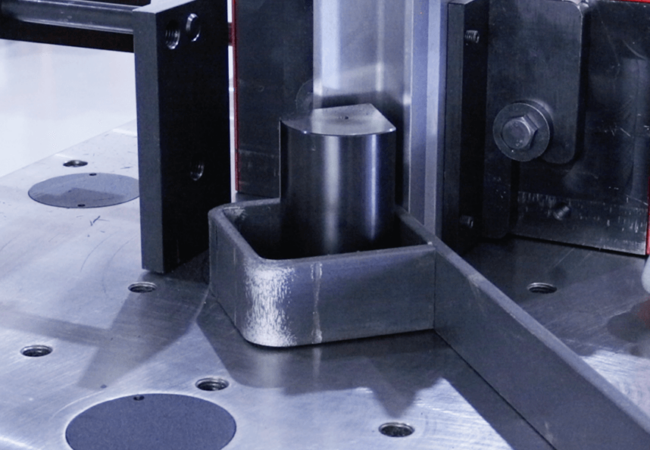

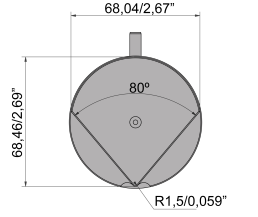

BENDING PUNCH AT 161 mm AND 80º

80º bending punch. The punch with an outer diameter of 70 mm allows for creating completely closed shapes with a minimum inner wing of 75 mm.

Reference: 131-16-01-00041 · P.70.80.R1.5

MAXIMUM BENDING LENGTH: 161 mm

Recent Comments