Revolutionizing Manufacturing: Fiber Laser Machines

Revolutionizing Manufacturing: The Efficiency and Time-Cost Savings of Fiber Laser CNC Cutting Machines

In the realm of modern manufacturing, technological advancements continually reshape the landscape, optimizing processes, and enhancing efficiency. Among these groundbreaking innovations stands the fiber laser CNC (Computer Numerical Control) cutting machine, a cutting-edge tool that has revolutionized the fabrication industry. Its precision, speed, and cost-effectiveness have made it a cornerstone of various industries, providing unparalleled efficiency and time-cost savings.

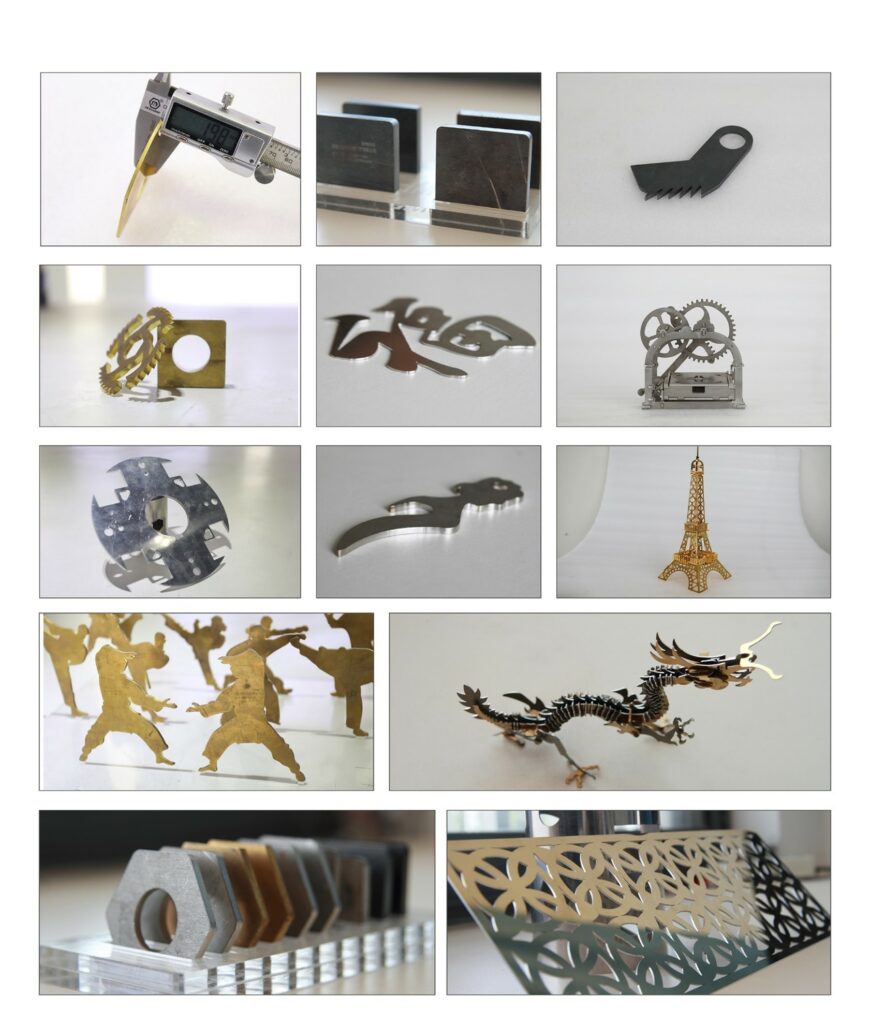

Fiber laser cutting machines utilize high-powered lasers generated from fiber optics to cut through a diverse array of materials with exceptional accuracy. From metals like mild steel, stainless steel and aluminum these machines offer versatility in cutting various thicknesses and shapes, meeting the demands of intricate designs and precise specifications.

Efficiency in Operations:

The efficiency of Fiber Laser CNC Cutting Machines is evident in their ability to significantly reduce production times compared to conventional cutting methods. The technology’s precision-focused laser beam swiftly navigates through materials, ensuring clean, accurate cuts with minimal waste. This efficiency translates into a remarkable increase in productivity, allowing manufacturers to meet deadlines more efficiently and take on larger volumes of work.

The high cutting speeds offered by Fiber Laser CNC machines are a game-changer, enabling rapid processing and quick turnaround times. This accelerated pace not only boosts production capacity but also minimizes lead times, giving businesses a competitive edge in the market.

The interchangeable cutting beds have improved the efficiency of these cutting machines even further. Our LF3015GA II model comes with this feature.

Moreover, these machines require minimal setup time and maintenance, reducing downtime and ensuring continuous operation. The integration of automation further optimizes workflow efficiency, as CNC technology allows for precise and repeatable cutting without constant human intervention.

Time-Cost Savings:

The time-cost savings achieved through Fiber Laser CNC Cutting Machines are substantial and multifaceted. Their ability to execute intricate cuts with precision minimizes material waste, thereby maximizing material utilization and reducing associated costs. This optimized use of materials results in significant savings for manufacturing businesses.

Furthermore, the precision and accuracy of laser cutting significantly reduce the need for post-processing or secondary operations. The finished products from Fiber Laser CNC machines often require minimal to no additional work, saving both time and labor costs. This streamlined production process not only accelerates manufacturing but also enhances the overall cost-effectiveness of operations.

Applications Across Industries:

The versatility and precision of Fiber Laser CNC Cutting Machines make them indispensable across a wide array of industries. Automotive, aerospace, electronics, furniture, and medical equipment manufacturing are just a few sectors benefiting from these cutting-edge machines. Their ability to handle intricate designs and various materials ensures their relevance in industries where precision and quality are paramount.

In conclusion, the efficiency and time-cost savings offered by Fiber Laser CNC Cutting Machines signify a paradigm shift in manufacturing processes. Their precision, speed, and versatility elevate productivity, reduce operational costs, and enhance the overall competitiveness of businesses. As technological advancements continue to unfold, these innovative machines will undoubtedly remain instrumental in shaping the future of manufacturing.

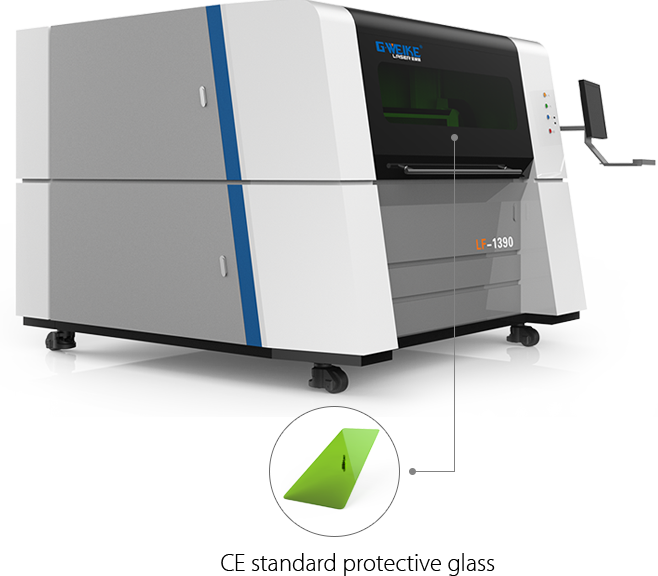

Check out our range of sheet cutting fiber laser cutting machine below:

- Sheet machine with Exchange table

- Mini- Sheet machine