CNC Profile Bender

Every steel workshop can take advantage of a Digibend

Euromac Digibend

Are you using or thinking to use a conventional press brake to bend small parts, thick material or bus bars? Then you need to look at a Digibend a powerful and versatile horizontal bending machine. Bending horizontally on a flatbed has two main advantages: – your part will always be perfect since you lay on a flat surface instead of referencing against two small fingers. – You can bend a closed loop (like a 9 shaped part), hence saving time and possibly also a welding operation. The Digibend takes advantage of this and with its unique features goes beyond.

More Information

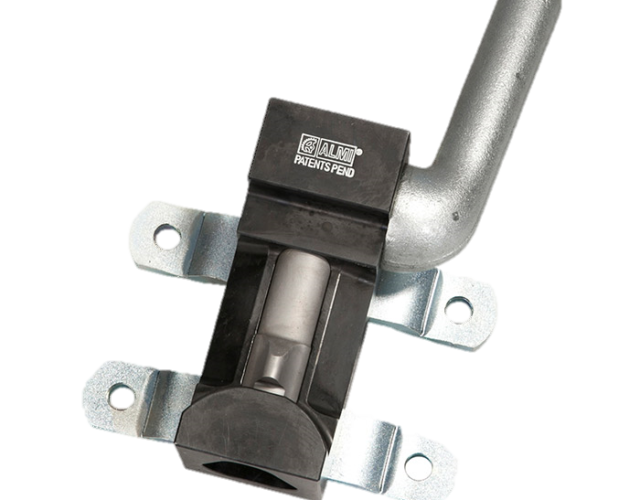

Euromac offers a variety of standard tools for a Digibend and changing from one tool setup to another is fast and easy. The Digibend table is a machined out of a single monoblock of Meehanite® 700N/mm2 (no welding points), the cylinder is completely embraced in the structure and the RAM is guided in all its stroke in order to be able to maintain the highest accuracy even in the high tonnage demanding applications. The strong structure combined with the unique control system and the specifically designed hydraulics ensure the repeatability accuracy (0,05 mm) even after thousands of bends. The flexible and strong design of the Digibend table (with anti marking treatment) together with the easy to use control system (2 axis CNC controlled) allows any customer to create their own custom tools for special applications.

| DIGIBEND | 200 | 200e | 400 | 800 |

| Max. pressure (kN) | 200 | 200 | 400 | 800 |

| Max. stroke (mm) | 195 | 195 | 245 | 345 |

| Max. working speed (mm/sec) | 9.6 | 9.6 | 9.6 | 9.3 |

| Min. working speed (mm/sec) | 4.8 | 4.8 | 4.8 | 4.6 |

| Return speed (mm/sec) | 48 | 48 | 62 | 45 |

| Average working speed (mm/sec) | 28.8 | 28.8 | 35.8 | 27.2 |

| Storables programs | 255 | 255 | 255 | 255 |

| Sequence of storables programs | 50 + 5 (for punching) | 50 | 50 + 5 (for punching) | 50 + 5 (for punching) |

| Number of bends for each sequence | 16 | 16 | 16 | 16 |

| Working table dimensions (mm) | 480 x 1060 x 925 (H) | 480 x 1060 x 925 (H) | 580 x 1230 x 925 (H) | 650 x 1565 x 925 (H) |

| Fixing holes in working table (nr. x Ø - mm) | 1 x Ø 80 / 2 x Ø 50 | 1 x Ø 80 / 2 x Ø 50 | 4 x Ø 80 | 6 x Ø 80 |

| Working height (mm) | 925 | 925 | 925 | 925 |

| Oil tank capacity (lt.) | 40 | 40 | 40 | 60 |

| Motore HP - Kw | 43134 | 43134 | 5.5 - 4 | 5.5 - 4 |

| High bending (mm) | H=200 | H=200 | H=200 | H=200 |

| Extra high bending (mm) | / | / | H=400 | H=400 |

| Shearing max thickness | H=150 x 6 (th) | H=150 x 6 (th) | H=150 x 10 (th) | H=150 x 12 (th) |

| Punching max thickness | Ø 30 x 5 (th) | Ø 30 x 5 (th) | Ø 30 x 10 (th) | Ø 30 x 12 (th) |

| Straightening (H/thickness) | H=200 | H=200 | H=200 | H=200 |

| Two-jaw-bending (mm) | Ø 42 | Ø 42 | Ø 60 | Ø 60 |

| Rotary bending (mm) | Ø 50 | Ø 50 | Ø 50 | Ø 50 |

| CNC automatic backguage (Length, mm) | 1250 / 2000 | NO | 1250 / 2000 | 1250 / 2000 |

| Approx. weight (kg) | 340 | 340 | 700 | 1500 |

| Overall dimensions (L x l x h) | 580 x 1060 x 1150 | 580 x 1060 x 1150 | 580 x 1230 x 1150 | 750 x 1565 x 1200 |