Drilling and Tapping CNC

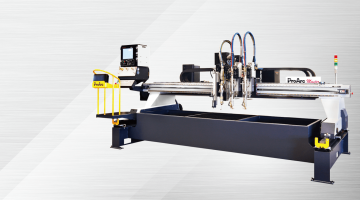

ProArc Gantry Drill+

ProArc Drill+ Gantry type auto drill machine is an automatic, efficient and high-performance CNC drilling & tapping machine.

It constitutes:

1. IPC based CNC controller

2. Servo Z-axis lifter

3. Servo drill spindle

4. Auto tool length detector

We make the drilling process easy, friendly and safe.

More Information

| Model | Unit | Drill+25 | Drill+30 | Drill+35 | Drill+40 | Drill+50 | Drill+60 | Drill+80 |

| Table size | mm | 1,700 x L | 2,200 x L | 2,700 x L | 3,200 x L | 4,200 x L | 5,200 x L | 7,200 x L |

| Parking space | mm | 1,500 | 1,500 | 1,500 | 1,500 | 2,000 | 2,000 | 2,000 |

| Z lifter effective stroke | mm | 350 | 350 | 350 | 350 | 350 | 350 | 350 |

| Track Length/section | mm | 3,000 | 3,000 | 3,000 | 3,000 | 3,000 | 3,000 | 3,000 |

| Plate thickness | mm | 100 | 100 | 100 | 100 | 100 | 100 | 100 |

| Positioning accuracy | mm | ±0.1 | ±0.1 | ±0.1 | ±0.1 | ±0.1 | ±0.1 | ±0.1 |

| Positioning speed | m/min | 16 | 16 | 16 | 16 | 16 | 16 | 16 |

| Number of spindle | set | 1~2 | 1~2 | 1~2 | 1~2 | 1~2 | 1~2 | 1~2 |

| Spindle model | Unit | DS-050 | DS-080 |

| Drive motor | hp | 15 | 30 |

| Drilling capacity | mm | Ø6~50 | Ø6~80 |

| Rotation speed | rpm | 10 ~ 2,000 | 10 ~ 2,000 |

| Effective length※1 | mm | 215 ~ 375 | 215 ~ 375 |

| Shank-standard | BT40-MT4 | BT50-MT4 | |

| Shank-tapping (option 1) | BT40-TPM830※3 | BT50-TPM830※2 | |

| Shank-tapping (option 2) | TPC830※3 | TPC830※3 | |

| Shank-indexible drills | BT40-SLA-OD | BT50-SLA-OD※4 |

※1 Effective length: From spindle nose-end to drills end

※2 Shank w/ tapping chuck

※3 Quick change tapping collets

※4 Shank w/ side lock holder

- AC Servo Z-axis lifter

Adopt ball screw feeding on Z axis with traveling speed 6,000 mm/min in 350mm stroke and is capable to support precise sequence control for primary, extremity and pecking process for the auto drilling process.

- IPC based CNC controller

Unique and intuitive GUI with touch panel

- Build-in Drill+ CAM in the controller

Can read .dxf file and edit on job site directly

- Quick release tool exchange device

Change tool in seconds

- Multi-task process

Multi-home position can be defined for different jobs and edit in one drilling process

- Auto tool length detector – one touch

Save measure time and keep accuracy

- Crossline laser point unit

Check position, support plate edge alignment, and tech mode

- Teach mode

Learn parts with multiple drill points and capable to edit drilling process without drawing

Boiler flange